Consult the Balyo 2024 impact report

3 Simple Steps from

No-Bot to Go-Bot in Your Warehouse and Manufacturing

At BALYO, we don’t just deliver automation—we make it effortless.

Our proven 3-step journey—Map, Simulate, Go—uses digital twin technology and advanced simulation tools to eliminate guesswork from your transition to AGVs/AMRs.

With collaborative software, flexible hardware, and deep industry experience, we turn complexity into clarity—guiding you from a manually operated warehouse or manufacturing facility to a fully autonomous one with precision and speed.

Step 1: Map

From Reality to Digital in a Day

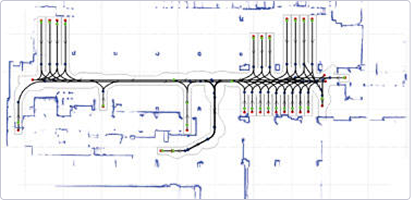

We kick things off by scanning your entire warehouse or manufacturing environment using BALYO’s handheld 3D LiDAR—capturing walls, racks, docks, paths, and pallet zones with millimeter precision.

This isn’t just a map. It’s the backbone of your digital twin—and the same data that powers your AGVs/AMRs.

No redundant installs. No extra programming. No added infrastructure.

You get more than a snapshot—you get a smart, scalable foundation:

✔ Identify pick/drop zones and flow logic early

✔ Customize pathways and restricted areas

✔ Spot optimization opportunities instantly

✔ Cut commissioning time dramatically

And it all happens in the first days of your automation journey.

Map once. Use everywhere.

Step 2: Simulate

Know Before You Go – With Zero Guesswork

With your digital twin in place, BALYO brings your future warehouse or manufacturing environment to life.

We simulate your operations—AGV and AMR movements, pallet flows, racking interactions, and interfaces with WMS, conveyors, stretch wrappers, and more.

Using AI-powered traffic management, we model:

✔ How many robots you actually need

✔ Your expected pallet throughput

✔ Interactions with your current automation systems

✔ Peak load scenarios and system responsiveness

Need shared-aisle logic or priority handling rules? We build it into your simulation.

You’ll see exactly how your future system will operate—before deployment begins.

Simulate it all. Prove the ROI. Go fast.

Step 3: Go

From Delivery to ROI—Fast

Once simulation is complete and approved, it’s time to go. Your BALYO robots—built on trusted OEM forklift platforms—arrive preloaded with your 3D maps, simulation data, and routing logic.

No delays. No custom builds.

During commissioning, we:

✔ Initialize the AGVs/AMRs

✔ Load maps and operational parameters

✔ Validate pick/drop points and flows

✔ Fine-tune robot behavior with real-time feedback

Thanks to the work done during Map and Simulate, integration time is cut by 50% compared to traditional automation projects.

Your robots already “know” your facility—they just need quick validation on-site to go live.

Your system ramps up faster, with minimal disruption and immediate results.

Why Choose BALYO?

Smarter AGV/AMR Automation for Warehouses and Manufacturing Floors

Higher Accuracy

We capture your real environment early and simulate every flow—avoiding guesswork and over-engineering.

Future-Proof Flexibility

Our digital twin enables easy updates to layouts, flow rules, and business logic as your operations evolve.

ROI Driven

Less waiting, more moving—so you start saving costs and improving efficiency sooner.

Scalable by Design

Our standard AGV/AMR process is repeatable across all your sites—deploy fast, scale faster.