Consult the Balyo 2024 impact report

3PL Industry Specifics

3PLs face rising labor costs and shrinking margins. Manual operations can't meet SLA speed at high rack heights.

INDUSTRY

- Site activity : Food-grade third-party logistics operations

- Quantity of shifts : 3+ shifts

- Country : Singapore

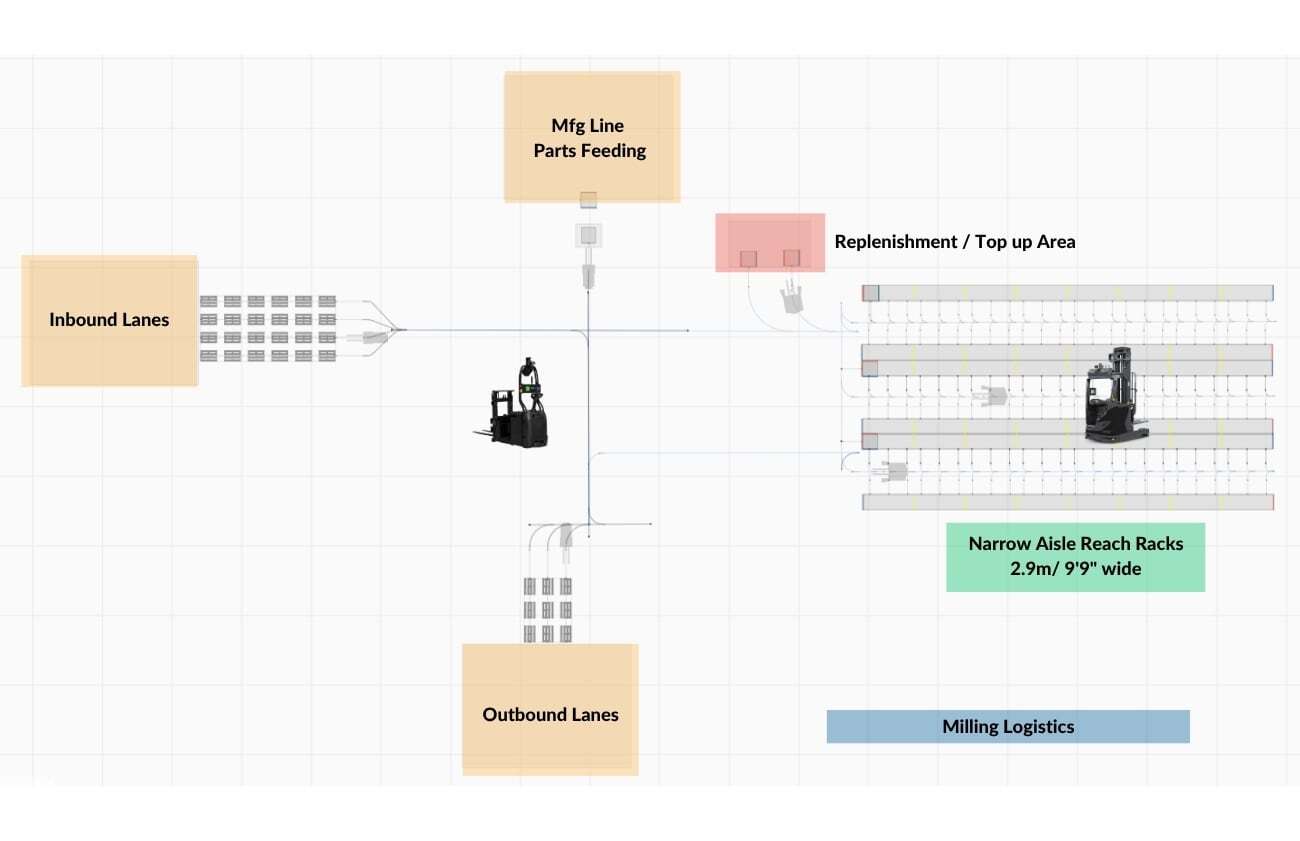

- Application : Full-cycle pallet movement from inbound receiving to outbound, with ultra-narrow aisle storage

Challenge

- Safety issues with forklifts above 12m

- Manual flow couldn’t support peak volumes

- Needed ROI inside a 3-year contract period

Solution

- VEENY VNA robot for high-bay pallet storage

- LOWY CB for pallet feeding and retrieval

- Real-time integration with WMS for mission planning

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today

Inbound goods arriving at 3PL receiving docks are scanned and staged directly into dynamic buffer lanes by BALYO’s LOWY CB autonomous stackers. Each pallet is immediately classified based on client identity, SKU profile, turnover velocity, and any special handling needs—laying the foundation for efficient flow and traceability.

Dynamic buffers are organized by expected dwell time and consolidation timing. Fast-moving SKUs are staged closer to outbound lanes, while slower items are routed deeper into the warehouse.

Directly integrated with the WMS, all key metadata—SKU, client ID, lot number, expiration—is captured and tracked.

From there, BALYO’s VEENY turret robots take over, transferring pallets into high-bay racking with precision. These VNA robots operate in ultra-narrow aisles and can stack loads up to 17 meters high—maximizing cube utilization and keeping the floor free for active operations.

When outbound orders are triggered—ranging from full-pallet deliveries to mixed-SKU shipments—VEENY units retrieve the appropriate pallets and deliver them to dynamic consolidation lanes. Orders are automatically grouped and sequenced for dispatch, reducing the need for manual sortation.

“In high-throughput 3PLs, automation isn’t just about speed—it’s the engine behind consistent SLA performance at scale.”

To enable rapid order fulfillment, a dedicated cross-docking flow is in place: pallets flagged for immediate shipment are intercepted by LOWY CB units at receipt and routed straight to outbound lanes, bypassing storage entirely. This enables same-day—or even sub-hour—turnaround when client SLAs demand it.

Throughout the operation, BALYO’s WMS integration and Storage Optimizer modules orchestrate everything from slotting to robot fleet balancing. The system constantly recalibrates pallet placement based on SKU movement, space availability, and client priorities. It also smooths inbound/outbound robot traffic during volume surges like peak seasons or flash campaigns—ensuring velocity never drops.

Key Operational Gains:

- Faster dock-to-dispatch turnaround for high-priority SKUs

- Automated VNA storage with 17m stacking capability

- Seamless cross-docking with zero manual touchpoints

- WMS-driven flow optimization across all pallet moves

- SLA-compliant service, even during peak volume periods

-

Why Automation Was Critical for Their Growth

As the 3PL facility expanded its customer base and SKU variety, manual operations quickly became a bottleneck—driving up labor costs, increasing order cycle times, and risking SLA violations.

Congestion during peak inbound and outbound windows created inefficiencies that manual forklift fleets could not overcome.

Automation enabled scalable 24/7 pallet handling, reduced loading and retrieval times, improved inventory traceability, and gave the 3PL the agility needed to meet growing multi-client demands without expanding labor headcount—essential for maintaining profitability and competitiveness in a high-pressure logistics environment.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Reduced fulfillment time, 24/7 readiness

- Eliminated storage errors and safety risks

- $1M+ in annualized savings per facility