Consult the Balyo 2024 impact report

Food and Beverage Industry Specifics

High-volume chocolate manufacturing is relentless. With nonstop production and strict hygiene requirements, pallet flow must be fast, safe, and absolutely reliable. Manual handoffs between wrapping and storage often slow things down—and break things along the way.

INDUSTRY

- Site activity: Chocolate production & pallet packaging

- Quantity of shifts: 3+ shifts

- Country: USA

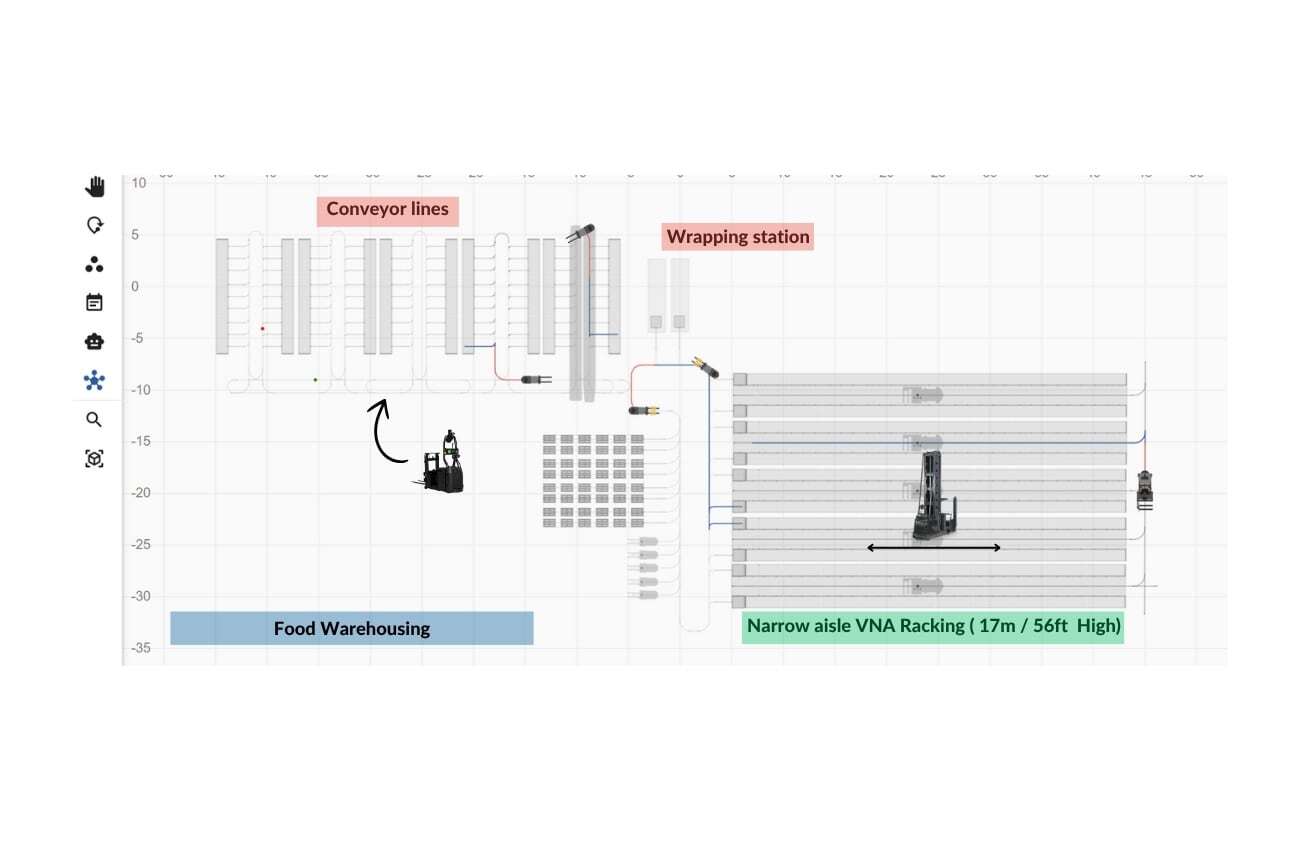

- Application: Wrapped pallet transfer to narrow aisle storage

Challenge

- Repetitive manual handling slowed flow from production to storage

- Product damage from inconsistent pallet movement

- Scaling operations required more space—but expansion isn’t an option

Solution

BALYO has deployed a fleet of infrastructure-free AGVs to automate your entire post-production flow:

- LOWY CB to pick up wrapped pallets straight from conveyors

- VEENY VNA robot to store them safely up to 17m/56ft high in narrow aisles

- 3D pallet perception ensuring precision in every single drop-off

From Manual Chaos to Scalable Automation

-

What Your Pallet Movement Could Transform with BALYO

After wrapping, finished chocolate goods are automatically picked up by BALYO’s counterbalanced stacker robots—LOWY CB—directly from the production conveyors.

These robots then transport pallets through dynamic staging zones, buffering inventory in real time to match shipping schedules, production flow, and available storage slots—seamlessly and without human intervention.

From there, REACHY, BALYO’s autonomous reach forklift, takes over. Capable of lifting to 11 meters, it stores pallets in high-bay racks—no manual forklifts required. Fast-moving SKUs are placed in accessible lanes, while slower movers are stored deeper, all fully managed through WMS integration.

When outbound orders are triggered—whether full pallets, mixed SKUs, or custom configurations—REACHY retrieves the right pallets and delivers them straight to dispatch staging zones, synchronized with your ERP and shipping plans.

“From conveyor to container, pallet flow is continuous, coordinated, and congestion-free—even during seasonal peaks.”

This closed-loop system ensures uninterrupted movement—from production to storage to shipping—with real-time decision-making and no bottlenecks, even during high-demand periods like holidays or new product launches.For operations requiring partial pallet picking or SKU consolidation, a dedicated manual picking zone can be added:

- Operators manually pick from inbound pallets

- BALYO robots then automatically re-store the remaining inventory

This hybrid workflow keeps inventory accurate and ensures continuous throughput.

At the center of this flow is BALYO’s AI-powered Storage Optimizer Solution:

- It recalculates optimal storage and retrieval patterns in real time

- Minimizes aisle congestion and idle travel

- Maximizes storage density and picking speed

Temperature-sensitive goods like chocolate also benefit. By minimizing dwell time and limiting door openings, the system helps maintain warehouse climate consistency, preserving product quality throughout the logistics cycle.

By orchestrating conveyor handoffs, robotic storage, buffer staging, flexible manual picking, and real-time optimization, BALYO enables manufacturers to achieve:

- Higher velocity across production and logistics

- Accurate, touch-free handling of every SKU

- End-to-end traceability and warehouse visibility

Whether scaling for seasonal peaks or aiming for year-round resilience, this automated setup is built for speed, precision, and flexibility.

-

Why Automation Could be Game-Changer for your Growth

Seasonal peaks in chocolate production can place extreme pressure on manual pallet handling, with risks of bottlenecks, inventory misplacement, and shipment delays.

Delicate chocolate goods also demand careful handling to avoid quality loss, while temperature fluctuations during longer manual cycles can threaten product shelf-life.Automation can enable chocolate producers to maintain continuous production flow, protect product quality, eliminate labor shortages, and ensure on-time deliveries during critical distribution windows—all while improving operational resilience in a highly competitive market.

-

Scalable by Design - Ready When You Are

Our systems are built to scale.

Adding new robots or expanding staging areas can be done without major infrastructure changes—giving you the flexibility to grow without disruption.

The same proven solution can be easily duplicated across multiple warehouses, offering a true enterprise-grade automation model.Whether scaling production, opening new distribution centers, or expanding globally, BALYO’s flexible model is ready to power your growth—on your timeline.

Results

- Zero pallet damage during movement and storage

- Nonstop operations, even during peak manufacturing cycles

- Scalable deployment across facilities with identical flow

- Over $1.5M in savings to be generated a year in a single site