Consult the Balyo 2024 impact report

Packaging Industry Specifics

Chocolate production moves fast—and so must your warehouse. But with narrow aisles and fragile packaging, manual forklifts just can’t keep up without breaking something.

INDUSTRY

- Site activity : Chocolate manufacturing with high-bay storage

- Quantity of shifts : 3+ shifts

- Country : USA

- Application : Finished goods putaway and retrieval up to 17m (56ft)

Challenge

- Operators struggled to store delicate pallets in VNA racks

- Constant risk of damage, delays, and labor shortages

- No time, space or budget—for major infrastructure changes

Solution

BALYO’s driverless VNA robot, VEENY, took over:

- Autonomously navigated 6 ft aisles and stored up to 17m/56ft high

- Integrated with WMS to match storage to outbound demand

- No change automation—effortlessly integrating into the existing system

From Manual Chaos to Scalable Automation

-

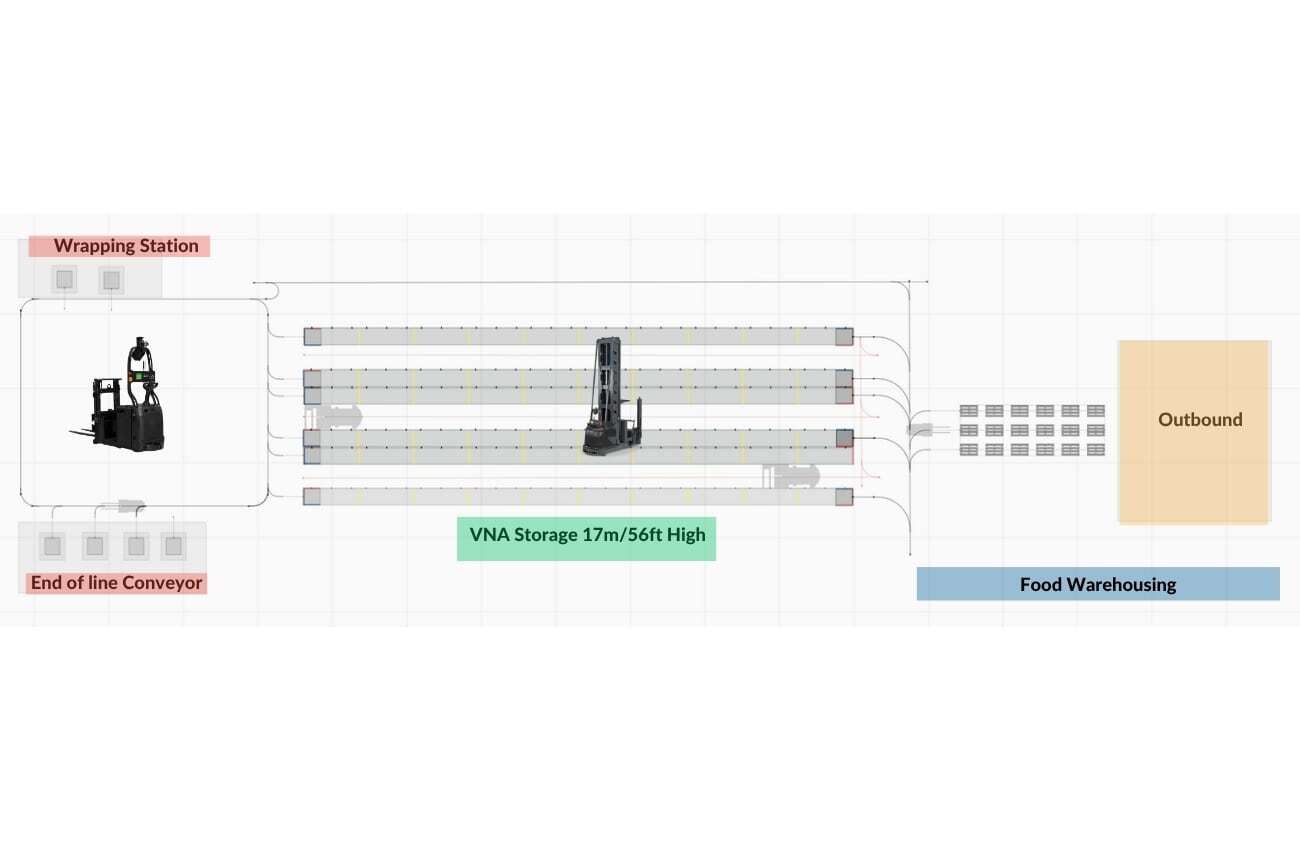

What Their Pallet Movement Looks Like Today

After wrapping, finished chocolate pallets are immediately collected by BALYO’s LOWY CB autonomous stackers stationed near end-of-line conveyors. These robots transfer wrapped pallets to dynamic inbound staging lanes, which are continuously adjusted based on outbound shipping schedules, SKU rotation, and storage availability.

Once staged, VEENY—BALYO’s autonomous very narrow aisle (VNA) turret robot—takes over. Designed for dense, high-rise storage, VEENY navigates ultra-narrow 1.8-meter aisles and places pallets up to 17 meters high, ensuring maximum cube utilization with minimal aisle congestion.

The result? More storage in less space, faster retrievals, and no forklift risks—perfect for fragile, high-turnover chocolate SKUs.

When outbound orders are released by the WMS, VEENY retrieves pallets and delivers them directly to outbound lanes, sequenced by dispatch priority and carrier timing. This ensures:

- Just-in-time staging

- Reduced dock dwell time

- Optimized trailer loading flow

For partial pallet consolidation or custom mixed-SKU orders, operators work in dedicated picking zones. Once selection is complete, BALYO robots collect remaining inventory and return it to high-bay storage, eliminating misplaced or delayed pallets.

Meanwhile, BALYO’s Storage Optimizer platform continuously adapts pallet slotting using:

- Real-time SKU demand forecasts

- Seasonal flow adjustments (e.g. holiday surges)

- Inventory velocity tiers

Fast-movers stay near outbound lanes. Slower SKUs are sent deeper into storage. Throughout, VEENY maintains safe, consistent vertical placement—reducing breakage risk for sensitive chocolate goods and fully replacing the need for high-reach forklifts.

The entire flow—from wrapping to staging to storage to dispatch—is fully orchestrated, delivering high-density storage, safer handling, faster throughput, and full pallet traceability in real time.

-

Why Automation Was Critical for Their Growth

Seasonal peaks in chocolate production created intense pressure on warehousing operations, especially in managing high SKU volumes and strict shipment deadlines.

Manual forklift operations struggled in ultra-narrow aisles, risking pallet damage and inefficient stacking, particularly at heights exceeding 15 meters.

Automation allowed the facility to maximize storage density, improve retrieval accuracy, protect product quality, and maintain outbound shipment reliability even during extreme production surges.

Driverless pallet handling also eliminated reliance on scarce skilled labor, allowing the operation to scale without workforce constraints.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Safer, more accurate pallet placement

- Fully scalable solution across all sites with 100+ robots at once

- $1M saved annually per site + 0 safety incidents