Consult the Balyo 2024 impact report

Dairy Industry Specifics

Dairy moves fast and spoils faster. You can’t afford delays between palletizing and dispatch—not with shelf life on the clock.

INDUSTRY

- Site activity : Temperature-controlled dairy manufacturing

- Quantity of shifts : 3+ shifts

- Country : New Zealand

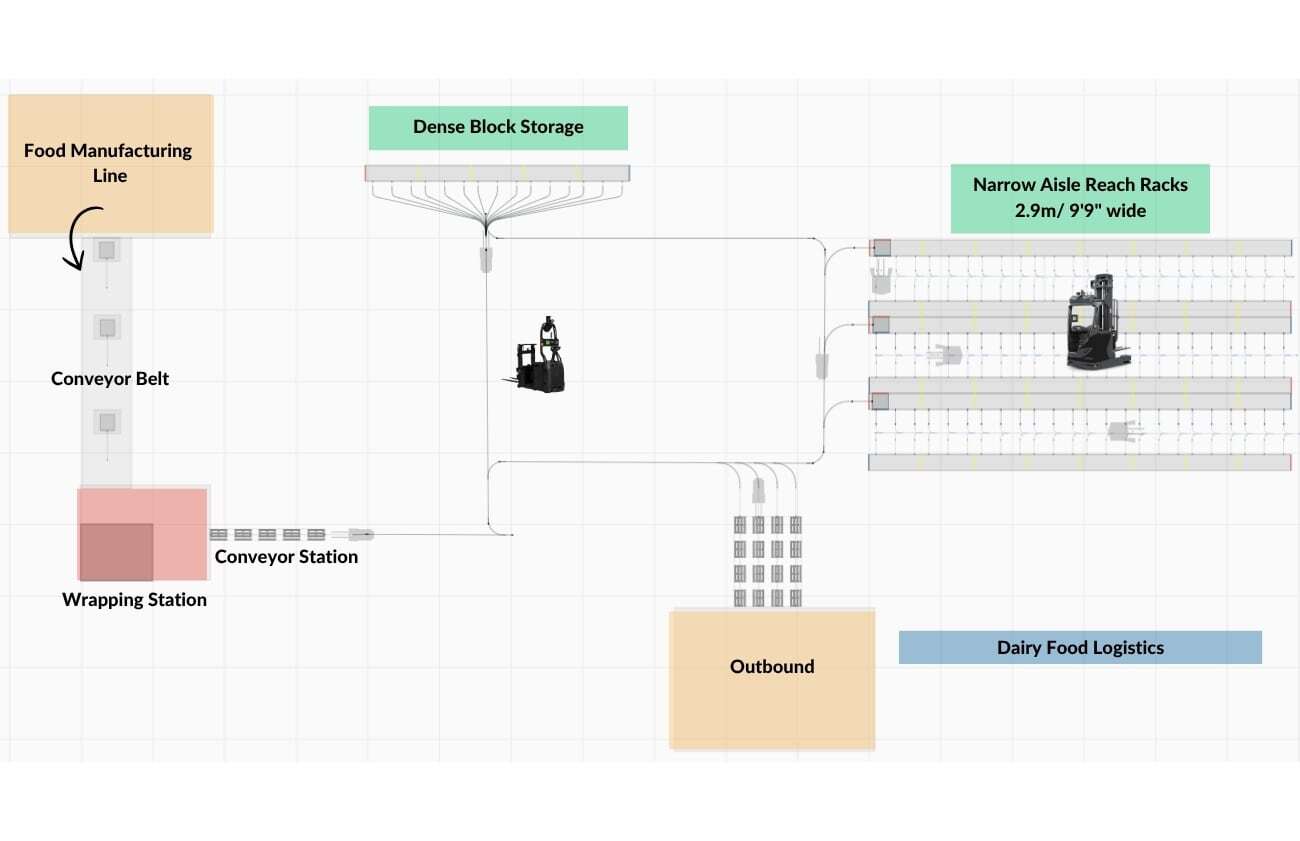

- Application : Production pallet transfer, narrow aisle putaway & block stacking

Challenge

- Manual pallet handling in cold zones = delays

- Needed FIFO storage and dynamic outbound flow

- Empty pallet recovery was inefficient

Solution

BALYO deployed:

- LOWY for end-of-line transport to cold storage

- REACHY for high-bay placement and staging

- Empty pallet loop to recycling and reuse

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today

Finished dairy product pallets are automatically picked up by BALYO’s LOWY CB autonomous stackers immediately after wrapping. These robots transport the pallets through insulated corridors into dynamic cold storage buffer zones located beside high-bay racking areas.

From there, REACHY autonomous reach trucks take over, placing pallets into racks designed for cold storage. These robots are engineered to operate seamlessly in low-temperature environments, ensuring consistent putaway performance up to 11 meters high without slowdown.

The operation strictly adheres to FIFO (First In, First Out) principles—essential for preserving shelf-life and meeting food safety regulations. Upon arrival, customer’s WMS or BALYO’s WMS, Storage Optimizer—logs each pallet’s expiration date and dynamically assigns a storage location that balances efficient retrieval paths with strict chronological rotation.

Strict FIFO enforcement through real-time WMS logic guarantees freshness while meeting dairy safety standards.

When outbound orders are triggered, REACHY retrieves pallets based on this FIFO logic and stages them in temperature-controlled outbound lanes, ready for rapid loading—minimizing exposure to ambient temperatures.

Production replenishment is fully automated as well:

- When empty pallet levels near the production zone run low, LOWY CB robots deliver fresh stacks of sanitized pallets from inbound staging areas.

- Simultaneously, used pallets from finished batches are collected and routed for cleaning, recycling, or reintegration into storage flows.

The Storage Optimizer continuously recalculates storage and retrieval paths in real time, accounting for live inventory changes, outbound priorities, and internal traffic. It also adjusts retrieval strategies based on shipping schedules and regional temperature forecasts, helping maintain cold chain integrity during transit.

By integrating temperature-resilient robots, real-time WMS coordination, and end-to-end automation, the dairy facility ensures uninterrupted cold chain management, faster turnaround, reduced waste, and consistently high product quality.

-

Why Automation Was Critical for Their Growth

Dairy production is a race against the clock—every minute matters for maintaining product freshness and regulatory compliance.

Manual handling was too slow, error-prone, and physically challenging inside refrigerated environments, risking shelf-life breaches and delayed shipments.

Automation allowed the facility to accelerate replenishment cycles, enforce strict FIFO rules without human error, reduce labor dependency in cold zones, and consistently meet tight food safety standards.

The result was higher throughput, lower wastage, and seamless cold chain continuity even during peak production periods.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- 24/7 dispatch flow without manual delays

- Optimized shelf life through smart storage

- Reusable pallet cycle improved sustainability