Consult the Balyo 2024 impact report

FMCG and Retail Industry Specifics

Empty pallet movement is a hidden drain—costing time, labor, and space. And it’s often overlooked in automation plans.

INDUSTRY

- Site activity : FMCG manufacturing with high pallet turnover

- Quantity of shifts : 2+ shifts

- Country : USA

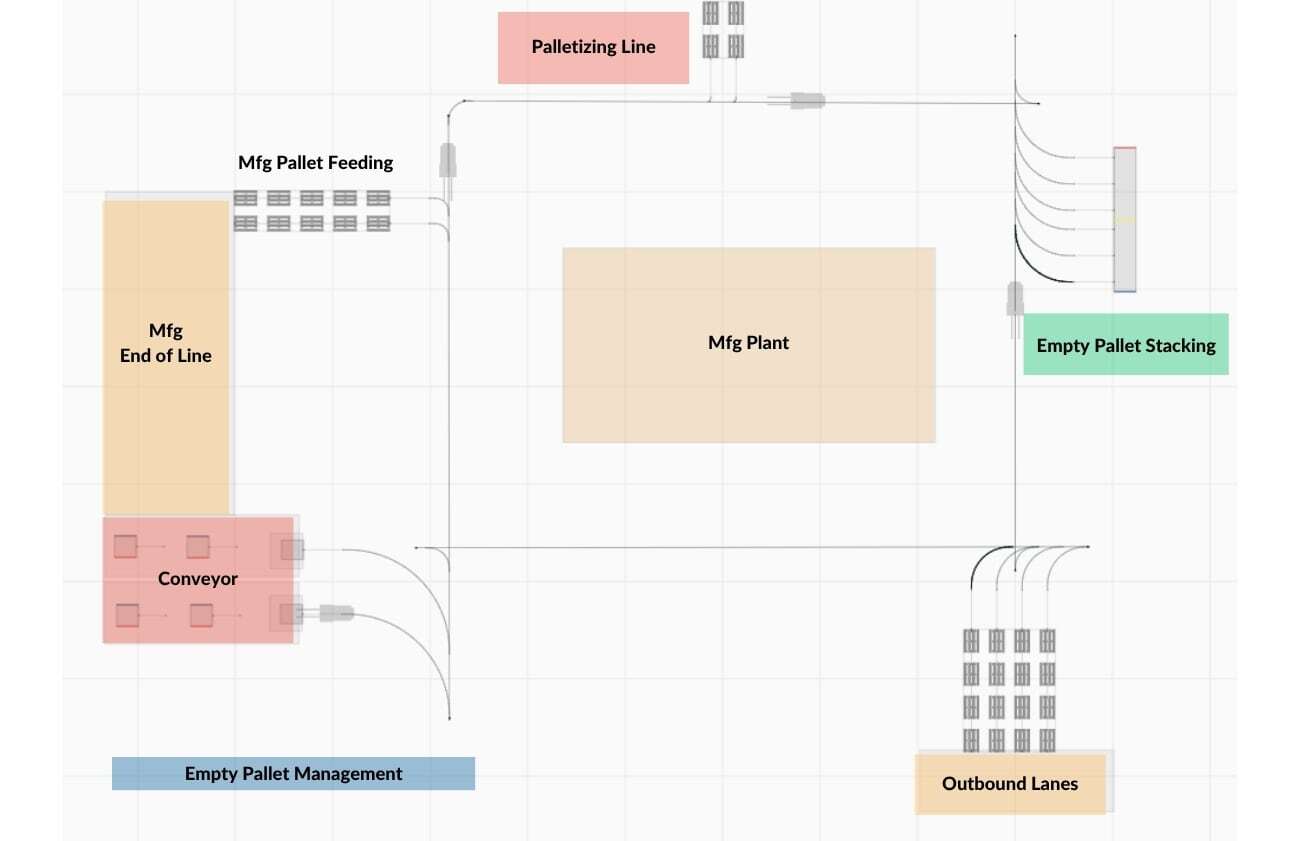

- Application : Line-side pallet feeding with empty pallet return cycle

Challenge

- Empty pallet flow was manual and inefficient

- Different types required manual sorting

- Valuable line-side labor was tied up

Solution

- LOWY CB handled all pallet types with 3D recognition

- Directed pallets to reuse, recycle, or storage zones

- Seamless integration with WMS and production cells

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today

In fast-paced production environments, uninterrupted access to empty pallets is non-negotiable. At this facility, BALYO’s LOWY CB autonomous stackers handle all empty pallet replenishment and return tasks—creating a closed-loop, zero-intervention cycle from storage to line and back.

Core Workflow Highlights:

- Automatic line-side buffer monitoring and replenishment trigger

- Real-time inventory tracking of empty pallet circulation

- Return & reuse or quality-directed sorting of used pallets

Each production line is assigned a buffer zone. As the count of empty pallets dips—either through WMS thresholds or live consumption detection—a LOWY CB robot is dispatched to restock from centralized pallet storage zones, ensuring just-in-time delivery.

Simultaneously, used pallets at the line are picked up by the same robot fleet. Reusable ones are returned to storage; damaged pallets are sent to quality control zones for inspection or disposal.

Pallets are the veins of production—and when they flow autonomously, the entire system stays alive and efficient.

BALYO’s WMS integration and Storage Optimizer engine continuously track the number, status, and location of all pallets. The system adjusts dynamically during high-volume peaks, prioritizing lines where downtime would create cascading bottlenecks.

No more last-minute calls for forklift drivers. No idle time waiting for pallets. No manual sorting of damaged stock.

Key Operational Gains:

- Autonomous replenishment and return without operator support

- Full traceability of pallet condition and movement

- Predictive insights for inventory and production coordination

- Priority-based mission planning to protect high-throughput lines

- Reduced labor needs and fewer line stoppages due to pallet unavailability

-

Why Automation Was Critical for Their Growth

In high-volume FMCG production, even brief delays in pallet replenishment can cause cascading line stoppages, missed shift targets, and reduced overall equipment effectiveness (OEE).

Manual empty pallet management was inefficient, error-prone, and left production vulnerable to unpredictable labor availability.

Automation guaranteed real-time empty pallet supply, eliminated hidden bottlenecks, freed up labor for higher-value production tasks, and safeguarded continuous production cycles—critical for meeting strict output targets in fast-moving consumer goods manufacturing.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Labor reallocated to production

- Closed-loop flow, no idle pallet congestion

- ROI in <18 months with $250K+ in annual savings