Consult the Balyo 2024 impact report

Pharmaceutical Industry Specifics

Healthcare logistics runs on accuracy and trust. One wrong pallet, one missed item—and it's not just costly, it’s risky.

INDUSTRY

- Site activity : Healthcare warehousing & pharmaceutical distribution

- Quantity of shifts : 3+ shifts

- Country : USA

- Application : Inbound pallet putaway, replenishment, and case picking

Challenge

- Thousands of SKUs with high rotation

- Manual errors during putaway and picking

- Strict GDP and safety regulations

Solution

BALYO’s LOWY + VEENY fleet enables you to:

- Intelligent storage up to 17m in narrow aisles

- Cold chain & FIFO management via WMS

- Hybrid workflows for manual case picking

From Manual Chaos to Scalable Automation

-

How Your Healthcare Logistics Could Transform with BALYO

Incoming pharmaceutical and healthcare pallets are first received and scanned at the facility’s inbound docks. During this step, each pallet’s SKU, batch number, expiration date, and temperature sensitivity is logged into the WMS. This ensures full regulatory compliance and total inventory visibility from the outset.

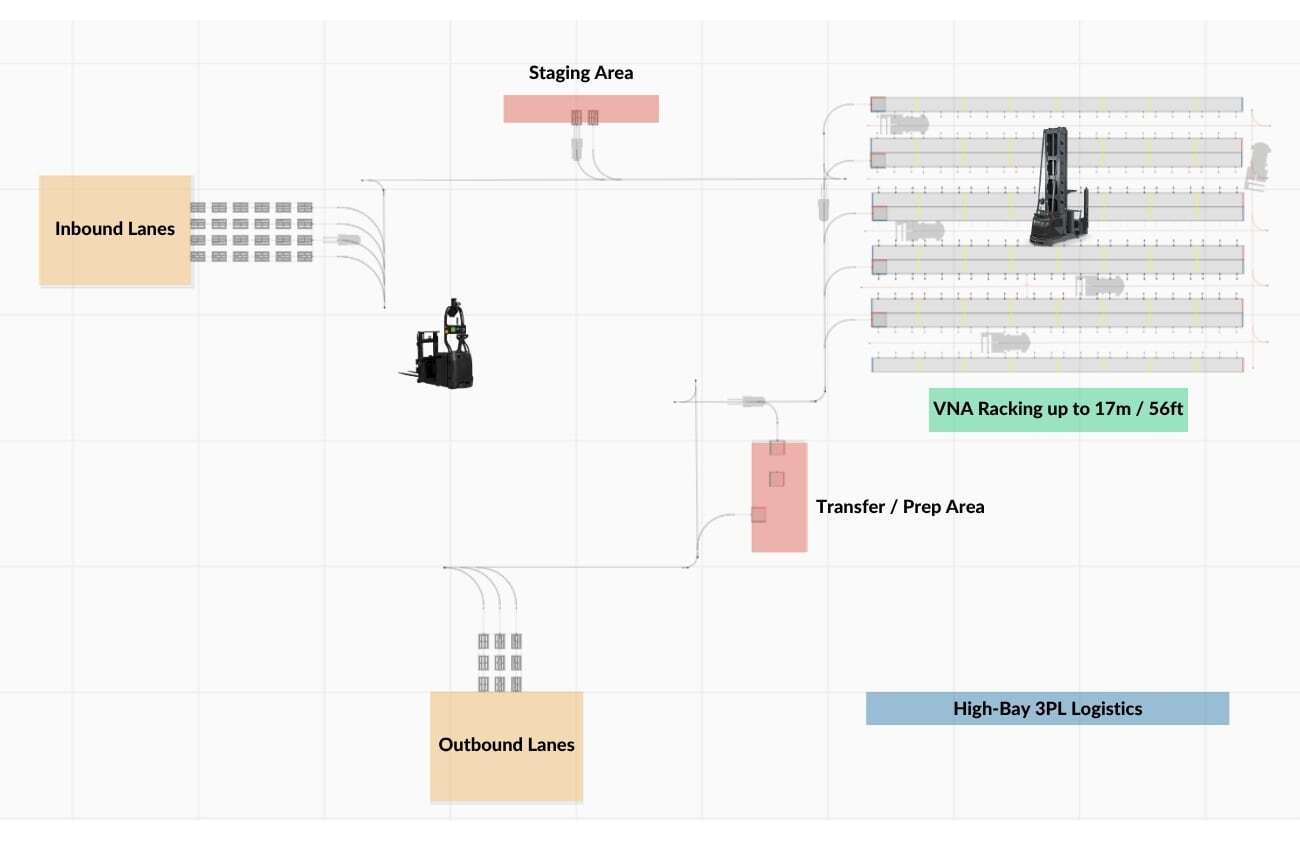

Once validated, BALYO’s LOWY CB robots autonomously transfer these pallets into dynamic inbound staging lanes. Pallets requiring specific conditions—like temperature-controlled environments—are automatically flagged for precise handling.

From here:

- BALYO’s VEENY turret robots handle deep storage, placing pallets into ultra-dense VNA racking systems up to 17 meters high.

- This high-density storage ensures maximum utilization while maintaining individual pallet traceability—critical for batch segregation, regulatory compliance, and recall readiness.

- Storage assignments are continuously optimized based on movement velocity, expiry, and compliance needs.

In regulated healthcare logistics, FEFO compliance and complete traceability are non-negotiable—not just for safety, but for legal accountability.

For temperature-sensitive pharmaceuticals, even a minor lapse in traceability or FEFO adherence can trigger costly recalls and risk patient safety.

When customer orders are received—be it full pallet shipments to hospitals or mixed-case picking for pharmacies—VEENY retrieves the assigned pallets with precision.

Retrieved pallets are routed to:

- Picking zones, where either full pallets are shipped or item-level picking occurs depending on order type

- Integrated barcode scans that preserve end-to-end traceability during every transfer

Once orders are picked, they enter dynamic outbound buffer zones, organized by:

- Carrier schedules

- Cold chain requirements

- Delivery urgency

BALYO’s Storage Optimizer continuously recalibrates picking paths, retrieval logic, and staging priorities. This ensures short-dated SKUs are prioritized through automated FEFO enforcement while longer-shelf-life stock is rotated accordingly.

Outbound lanes are designed to minimize product dwell time and reduce the risk of temperature swings—especially vital for sensitive drugs, vaccines, or biologics.

With automation from inbound to outbound—including dynamic slotting, high-bay storage, and compliant order handling—your facility can achieve:

- Faster order turnaround

- Full regulatory traceability

- Lower human error risk

- Higher throughput and warehouse efficiency

- Safer, compliant patient outcomes

-

Why Automation Could Be a Game-Changer for Your Growth

In pharmaceutical warehousing, manual errors are not just operational risks—they can become threats to patient health and regulatory compliance.

Manual pallet handling can expose operations to risks of mispicks, loss of traceability, and temperature breaches during handling transitions.

BALYO’s automation solutions can deliver 100% SKU traceability, reduce manual handling risks, and enforce strict GDP (Good Distribution Practice) compliance across the entire inventory lifecycle.

Automation can also maximize ultra-dense storage capacity while maintaining real-time visibility and audit-ready documentation—critical for scaling operations in the highly regulated healthcare sector.

-

The Scalability Factor – Ready When You Are

Our systems are designed for effortless scaling.

Adding new robots or expanding dynamic storage areas can be done without major infrastructure changes.

The same proven robotic solutions can be duplicated easily across multiple sites, delivering a true enterprise-grade automation model.

Whether you're expanding production capacity, opening new distribution centers, or scaling internationally, BALYO’s flexible model can adapt to your growth needs—ready to deliver results whenever you are.

Results

- Compliance without compromise

- Precise, damage-free handling

- Continuous replenishment with zero downtime