Consult the Balyo 2024 impact report

FMCG and Retail Industry Specifics

Wrapped pallets and consumer health goods require careful handling and traceability—especially in automated QC or QA environments.

INDUSTRY

- Site activity : Healthcare product packaging & wrapping

- Quantity of shifts : 2+ shifts

- Country : USA

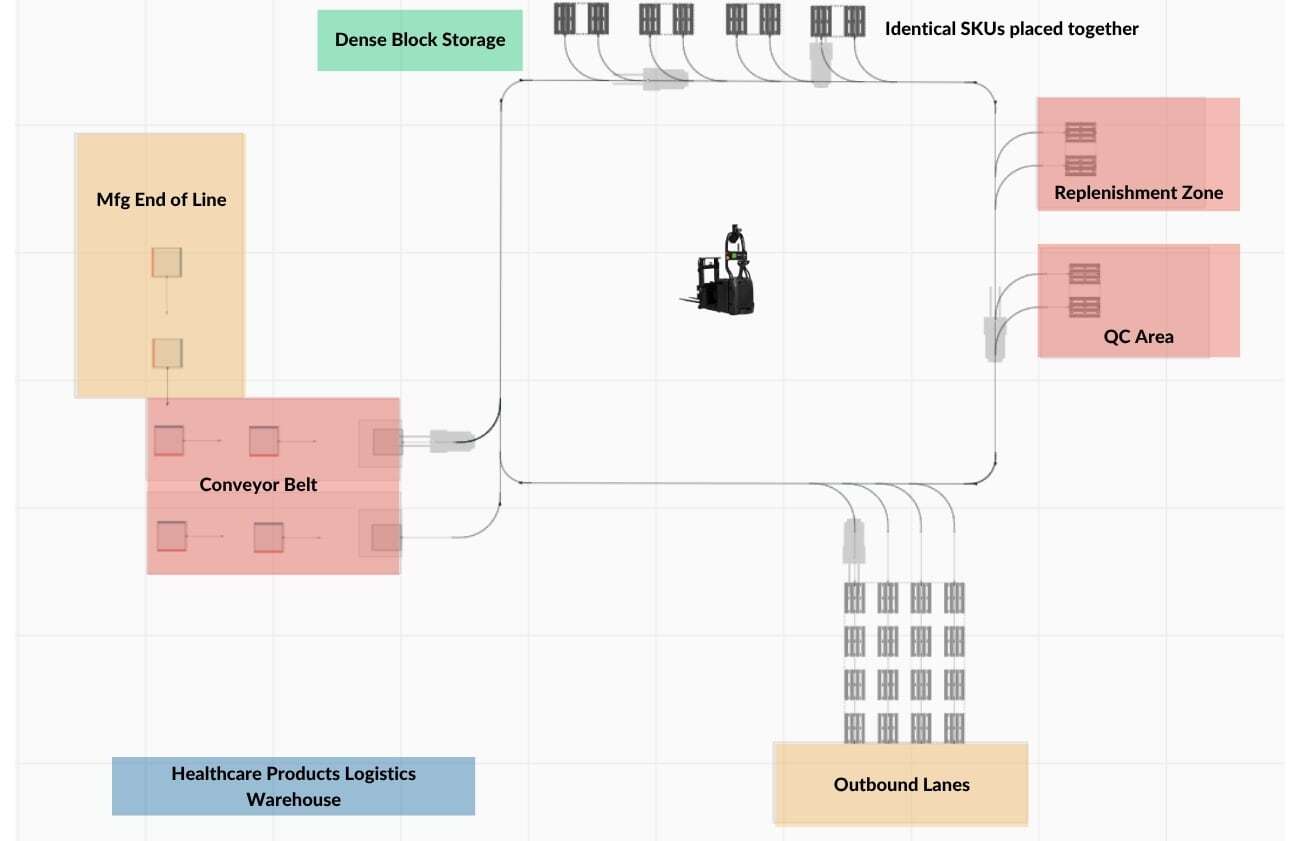

- Application : Double-stacked pallet handling from end-of-line to outbound staging

Challenge

- Needed to double-stack fragile pallets without damage

- Manual handling caused traceability and safety issues

- QC zones weren’t accurately sorted

Solution

- LOWY CB automates double stacking at end of line

- Barcode scans direct pallets to QC or dense storage

- Fully integrated with existing conveyors and WMS

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today

Freshly wrapped pallets at the end of healthcare production lines are immediately retrieved by BALYO’s LOWY CB autonomous stackers. Positioned directly at end-of-line conveyors, these robots eliminate delays and reduce human handling of sensitive medical goods.

Key flow highlights:

- Safe double-stacking managed entirely by AGVs based on SKU weight and compliance

- WMS integration ensures real-time validation of all stack combinations

- Outbound staging adapts live to carrier arrivals and changing shipping windows

When required, BALYO’s AGVs perform double-stacking operations with strict adherence to healthcare logistics standards. Stack eligibility is determined through WMS rules—no heavy pallets over fragile items, and no manual judgment calls.

In healthcare logistics, the cost of an error isn't just operational—it’s clinical. That’s why full-stack automation from line to dock isn’t optional. It’s essential.

Once stacks are validated, pallets are transferred to dynamic outbound staging lanes, organized by truck route, dispatch timing, and customer delivery windows. Trailers are loaded in optimized sequence to maximize capacity and avoid rehandling.

If dispatch priorities shift—early carrier arrival, rush order, missed slot—AGVs automatically reshuffle outbound lanes. The system adjusts in real time, ensuring trucks leave on time with the correct load.

No forklifts. No delays. No guesswork.

Every movement is logged into the WMS: stack status, batch numbers, pallet ID, compliance checks. This provides a full audit trail—critical for regulated medical and pharmaceutical logistics.

Key Operational Gains:

- Autonomous double-stacking with compliance enforcement

- Zero-touch handoff from production to dock

- Dynamic outbound lane sequencing for optimal load plans

- Real-time responsiveness to dispatch changes

- Full traceability and regulatory documentation for each pallet

-

Why Automation Was Critical for Their Growth

Manual double-stacking and pallet handling at the end of healthcare production lines introduced major risks: inconsistent stacking, shipment delays, increased workplace injuries, and potential damage to sensitive medical goods.

In an industry where product integrity directly impacts patient safety and regulatory compliance, these risks were unacceptable.

Automation standardized stacking quality, ensured 100% weight compliance, improved trailer space utilization, and reduced handling risks across critical shipping flows.

It also strengthened traceability and audit readiness—essential for maintaining certifications and customer trust in the healthcare supply chain.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- 100% SKU traceability

- No more costly rework from safety incidents

- ~$250K/year savings per site through labor, space, and damage reduction