Consult the Balyo 2024 impact report

Manufacturing Industry Specifics

Milling environments deal with heavy, irregular parts across multiple zones. Manual pallet handling drains labor, slows throughput, and increases risk.

INDUSTRY

- Site activity : Component feeding for manufacturing lines

- Quantity of shifts : 3+ shifts

- Country : Australia

- Application : Pallet retrieval for line dispatch and production replenishment

Challenge

- Needed precise, flexible movement across receiving, storage, and dispatch

- Manual handling caused delays and errors

- Labor shortages impacting reliability

Solution

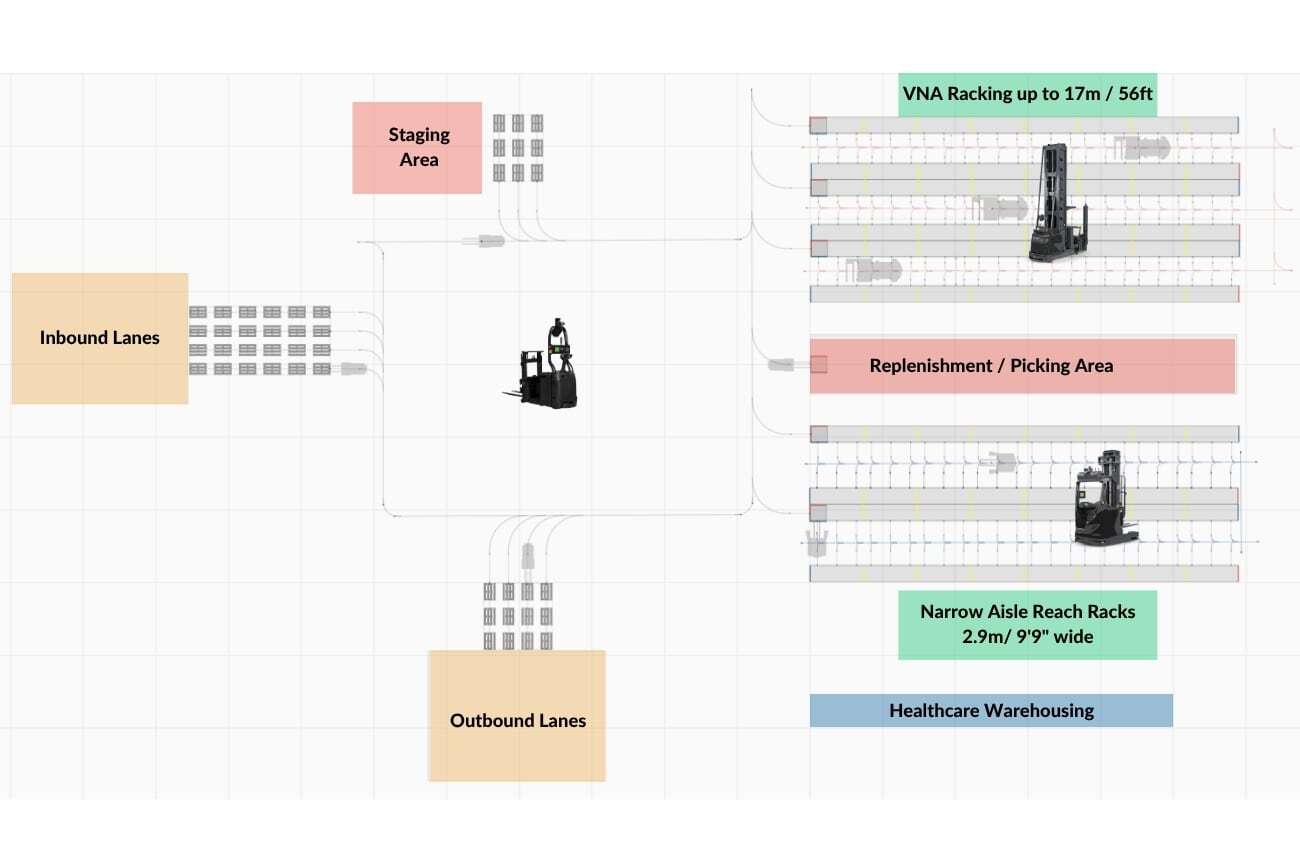

- REACHY for vertical storage up to 11m

- LOWY CB for horizontal transfers and line-side deliveries

- Replenishment loops and dispatch fully integrated with WMS

From Manual Chaos to Scalable Automation

-

How Your Logistics Could Transform with BALYO

Inbound heavy pallets containing raw metal parts or unfinished assemblies are automatically collected at receiving docks by BALYO’s LOWY CB autonomous stackers. Built for safe handling of high-weight loads, these robots eliminate the need for manual forklifts or pallet jacks in receiving areas.

LOWY CB units transport these pallets into dynamic buffer zones placed strategically near CNC machining cells and key production lines. Each buffer zone is continuously optimized based on part types, real-time floor layouts, and WMS-driven production schedules—ensuring raw materials are always positioned for immediate retrieval without creating staging bottlenecks.

When a CNC machine sends a material request—whether through floor sensors, ERP triggers, or WMS stock levels—BALYO’s REACHY autonomous reach trucks retrieve the assigned pallet from buffer zones or storage racks and deliver it directly to the line-side station. This tight integration keeps machines running with minimal downtime, eliminates manual handoffs, and ensures smooth batch transitions.

In high-mix, high-weight manufacturing, automation isn't a luxury—it's the difference between predictable flow and constant firefighting.

As parts progress through CNC stages, BALYO robots collect finished or semi-finished goods. Based on downstream workflows, these can either be:

- Moved into dynamic holding zones for secondary processing

- Or routed to outbound staging lanes for final shipment prep

At the center of it all is BALYO’s Storage Optimizer, which orchestrates both inbound material handling and finished goods dispatch. It dynamically adjusts pallet storage slots in real time, factoring in production urgency, machine load, and shipping timelines.

Dynamic buffers are continuously recalibrated to maintain floor fluidity: high-priority orders are staged closer to the action, while bulk or slower-turnover items are routed deeper into storage. The system also tracks empty pallet returns—automating their collection and reintegration into the workflow to keep line-side areas clutter-free and production-ready.

Key Operational Gains:

- Reduced downtime with real-time CNC machine feeding

- No manual handling of heavy inbound loads

- Flexible buffer zones aligned to production velocity

- Automatic finished goods routing based on next-step logic

- Continuous throughput across multi-shift environments

-

Why Automation Was Critical for Their Growth

Handling heavy pallets manually is not only slow and inefficient—it can significantly increase the risks of workplace injuries, equipment damage, and costly production delays.

Manual delays in raw material feeding can directly impact CNC machine uptime, drive up production costs, and jeopardize delivery schedules.

BALYO’s automation solutions can ensure faster raw material delivery, minimize human safety risks, increase CNC uptime, and lay the foundation for scalable multi-shift operations—without adding proportional labor costs.

-

The Scalability Factor – Ready When You Are

Our systems are designed for effortless scaling.

Adding new robots or expanding dynamic storage areas can be done without major infrastructure changes.

The same proven robotic solutions can be duplicated easily across multiple sites, delivering a true enterprise-grade automation model.

Whether you're expanding production capacity, opening new distribution centers, or scaling internationally, BALYO’s flexible model can adapt to your growth needs—ready to deliver results whenever you are.

Results

- Full-cycle automation from receiving to top-up to dispatch

- Freed up labor for production tasks

- ROI in <18 months with ~$1M/year savings per site