In third-party logistics, time is the only non-renewable resource. Our clients tell us that every minute goods are not moving is a minute of lost revenue and broken service-level agreements. The single greatest enemy to profitability is downtime. Yet, for decades, the industry has accepted a model built around it. We plan for downtime: shift changes, employee breaks, weekend closures, and the inevitable performance drop-off from fatigue.

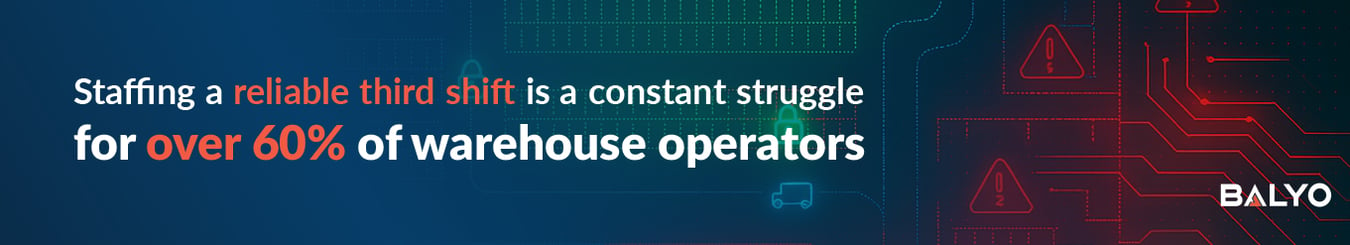

This is the fundamental flaw of a purely manual operation: it is inherently discontinuous. The U.S. Bureau of Labor Statistics reports that night shift workers are paid, on average, a 5-10% wage premium¹, and even then, staffing a reliable third shift is a constant struggle for over 60% of warehouse operators². We have engineered a system that is designed to stop.

The time for accepting this limitation is over. The advent of intelligent automation heralds a new era—one of continuous operations. This is not an incremental improvement; it is a fundamental re-architecting of the warehouse. By deploying a reliable, autonomous forklift fleet, a 3PL can transform its facility from a series of stops and starts into a constant, predictable, and highly profitable flow of goods.

This is the end of downtime as we know it.

The High Cost of a Discontinuous Day

For the Financial Analyst and General Manager, the cost of a stop-and-start operation is a significant and often underestimated drain on P&L. Industry research estimates the average cost of just one hour of operational downtime can range from $100,000 to over $300,000, depending on the scale of the facility³. While this figure is often associated with catastrophic failures, the "micro-downtimes" of a manual operation add up to death by a thousand cuts.

Consider the daily friction points:

- Shift Handovers: Productivity dips as one shift winds down and another ramps up, a process that can burn 30-60 minutes of productive time twice or three times a day.

- End-of-Shift Fatigue: Error rates for manual tasks can increase by as much as 25% in the final hours of a long shift⁴, leading to costly rework, damaged goods, and safety incidents.

- Labor Scarcity: An inability to fully staff a second or third shift means assets—your building, your racking, your systems—are underutilized for a third of every day.

This problem is massively amplified during seasonal peaks. The pressure to scale a manual workforce leads to what we call "peak season panic"—a frantic reliance on expensive overtime and undertrained temporary labor, which drives inefficiency and risk. This is not a sustainable model for growth.

The Uptime Trifecta: Hardware, Software, and Power

Achieving true continuous operations requires an unwavering foundation of reliability. It’s a trifecta of robust hardware, intelligent software, and perpetual power, all working in concert.

- Robust Hardware: Uptime starts with the machine itself. A 3PL automated robot must be built for the rigors of industrial use. This is why BALYO autonomous AGV forklifts begin with a world-class OEM forklift chassis. These are vehicles with millions of hours of proven operational life, engineered for durability. We then integrate industrial-grade sensors and controllers, creating a warehouse robot designed for constant motion.

- Intelligent Software: The Robot Manager is the brain of the 24/7 operation. It’s the air traffic controller that orchestrates the entire fleet, managing tasks, optimizing routes, and, most importantly, making intelligent decisions to maximize fleet availability.

- Perpetual Power: The single biggest enabler of continuous operations is automated battery management. Using advanced Lithium-ion batteries and an intelligent Robot Manager, the system eliminates the need for manual battery swaps. This is the key to unlocking 24/7 runtime.

Beyond Uptime - The Predictability Advantage

A system that runs 24/7 is powerful. A system that runs 24/7 with machine-level predictability is transformative. Manual performance is variable; it degrades with fatigue, distraction, and time. A 3PL automated robot's performance is constant. It executes the 10,000th pallet move of the week with the exact same precision, speed, and safety as the first.

This predictability revolutionizes operational planning:

- Data-Driven Forecasting: You can forecast throughput and labor needs with unparalleled accuracy because the baseline material transport is a known constant.

- Optimized Labor Allocation: With robots handling the predictable, repetitive transport, you can deploy your human team to high-value, exception-based tasks where they can make the biggest impact.

- Enhanced Service Levels: Your ability to meet and exceed customer SLAs becomes far more reliable because your operation is insulated from the volatility of manual labor performance.

With automated guided vehicles, the question is no longer "How much can we get done today?" but rather "What is the optimal flow rate for our facility?"

The 'Lights-Out' Reality for 3PLs

The term "lights-out" conjures images of a completely empty warehouse with robots silently working in the dark. While this is technically possible, it’s not the most strategic or realistic goal for a dynamic, multi-client 3PL. The true future is not about eliminating humans, but about elevating their role.

The practical and powerful vision for a 3PL is a "lights-on / lights-out" hybrid model:

- Lights-On (Shifts 1 & 2): Your skilled human workforce is on-site, performing complex, value-added tasks: receiving, quality control, custom kitting, exception handling, and loading complex outbound trailers. They are supported by the autonomous fleet, which handles all the point-to-point material transport.

- Lights-Out (Shift 3 & Weekends): The primary workforce goes home. The lights go down. And the robot fleet continues to work. They spend the night pre-positioning inventory for the morning shift, performing long-haul transfers, and clearing docks—all without human intervention.

This model allows a 3PL to achieve 24/7 asset utilization without the immense cost and challenge of staffing a full third shift. It’s a pragmatic approach to creating a truly continuous operation.

Make Uptime the Planning Standard

For too long, 3PLs have managed their operations around the limitations of downtime. The technology to eliminate it is no longer a future concept; it is a proven, deployable reality. By combining industrial-grade automated guided vehicles with intelligent fleet and power management, continuous operations become the new standard. It's time to stop planning for downtime and start designing for constant flow.

Ready to calculate the ROI of continuous operations? Contact our automation experts for a personalized uptime assessment.