Consult the Balyo 2024 impact report

Consult the Balyo 2024 impact report

FOCUS

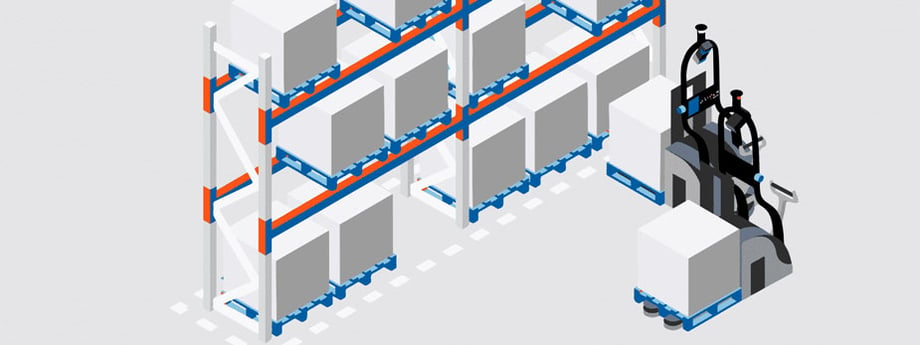

With an ever-increasing demand, warehouses face a huge challenge of stacking/stocking loads and maximizing the storage space, especially in regions where cost per square meter is high.

The most common form of stacking is a standard racking. This type of rack is used when there is a relatively higher number of pallets per SKU and requires complete access to each individual pallet. Compared to block stacking, it can be configured in a number of ways, which are managed by WMS.

A relatively lower warehouse optimization and storage density means that the racking operations can be complex, especially for manually operated trucks, as operators have to be careful (particularly at heights) in storing and retrieving pallets. This takes a toll on operational efficiency.

With Driven by BALYO robots, companies can deploy robots to handle the task of storing and retrieving pallets from the racks with high precision and efficiency.

SOLUTIONS

WMS Interface : An example would be a pallet of finished goods that needs to be stored in high racks as buffer before shipping. BALYO robots can interface with the WMS/ERP and be tasked with a mission to store the pallet onto the designated rack. Using a 3D Camera, the BALYO robot also checks for free space before placing the pallet on the rack, thus providing a secure and efficient operation.

AFFILIATE PRODUCTS

FOCUS

In applications where the customer has a low level of load rotation and needs space optimisation, block stacking is the answer. Block stacking does not require any storage equipment, instead loaded pallets are placed directly on the floor and built up to a maximum stable height. Although it can optimize warehouse space up to 90%, this type of storage is only applicable for loads with low handling frequency and/or a uniform load type. Lack of infrastructure also means that pallets needs to be placed precisely on top of each other for safety. This makes the manual operations tedious and time consuming.

BALYO robots are able to execute precise and critical block stacking operations with the help of its safety first technology. A camera sensor placed below the forks (and an optional one on the load backrest), first scans and monitors the free space before placing the load.

SOLUTIONS

3D Camera : For example, an assigned robot equipped with a 3D camera, picking in the mass storage area, will raise its forks just above the drop off height indicated by WMS, and if clear, proceeds to place the load carefully, thus providing secure and fast operations.

Additionally, robots can also distinguish between pallets and transportation goods, control its forks to store and retrieve loads with high precision.

AFFILIATE PRODUCTS

Autonomous Robots for load movements

Revolutionize your logistics operations with intelligent robots designed to automate your load handling.

Join our newsletter

Stay Ahead with Automation Insights !