Consult the Balyo 2024 impact report

3PL Industry Specifics

Large 3PLs must process high volumes with little margin for error or delay—especially in contract-bound facilities.

INDUSTRY

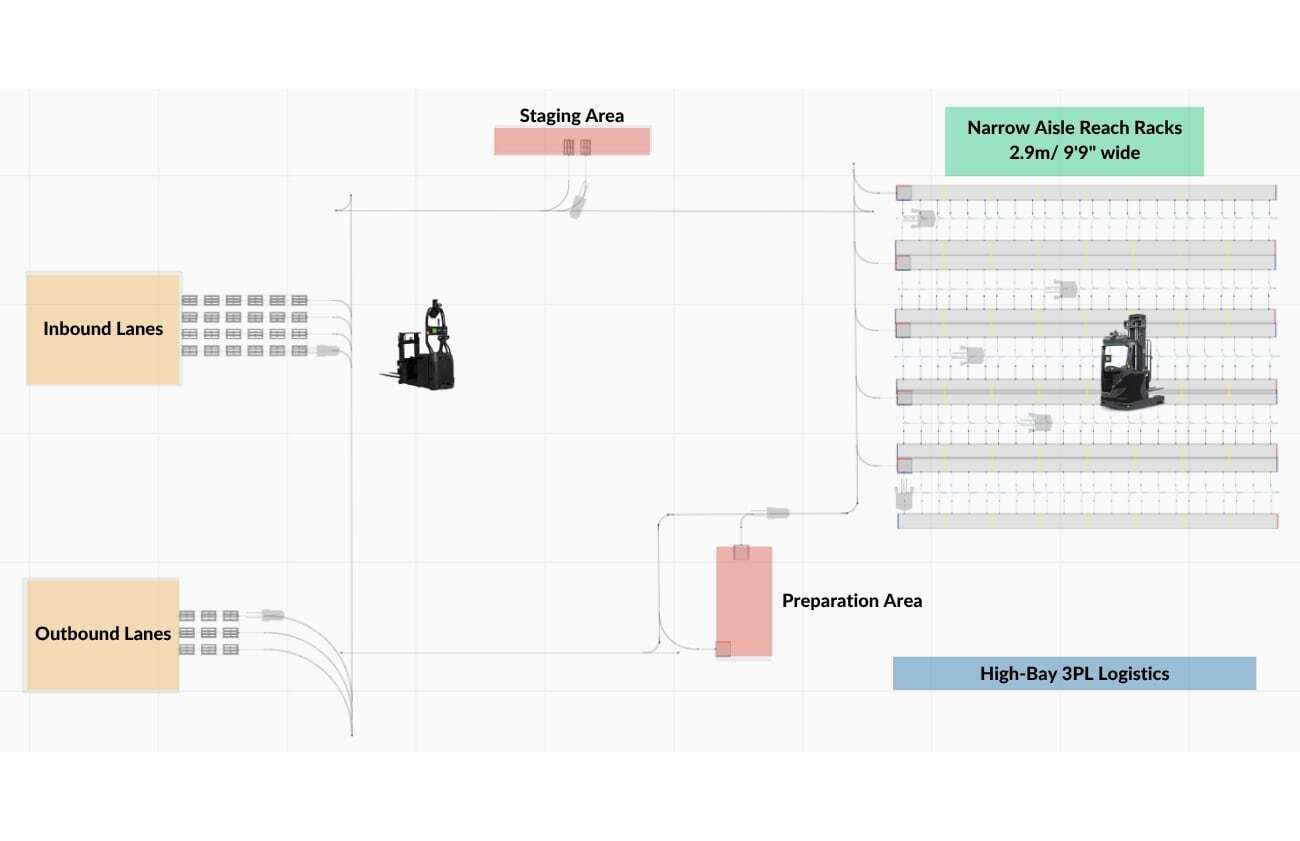

- Site activity : Third-party logistics warehousing

- Quantity of shifts : 3+ shifts

- Country : Germany

- Application : Conveyor-based inbound handling and automated narrow aisle storage

Challenge

- Manual storage created delays at sortation

- Needed dense, safe high-bay racking integration

- Production and storage lacked sync

Solution

- REACHY picks from conveyor and places up to 11m

- Smart placement based on WMS data

- Continuous high-speed pallet flow between zones

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today

Inbound pallets arriving at the 3PL facility’s receiving docks are scanned and moved into dynamic staging zones by BALYO’s LOWY CB autonomous stackers. Each pallet is logged into the WMS with full SKU and client ownership data for complete traceability.

Highlights of the flow:

- Dynamic zones prioritize storage based on SKU velocity, SLAs, and shipment urgency

- All pallet metadata is captured at receipt to enable precise tracking and compliance

- High-turnover SKUs are staged closer to outbound lanes for faster retrieval

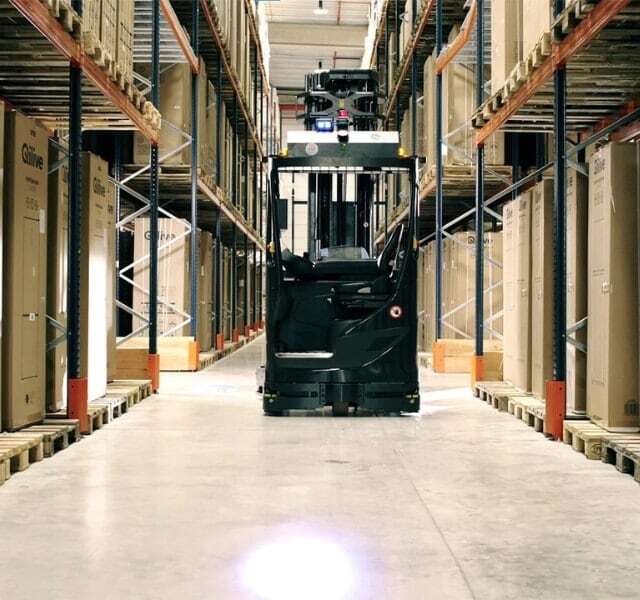

From these buffers, BALYO’s VEENY very narrow aisle (VNA) turret robots take over. Designed for extreme precision in tight aisles, they store pallets in high-bay racks up to 17 meters—maximizing vertical cube utilization and freeing floor space for active operations.

Storage is optimized not just for density, but also for retrieval speed. Fast-movers are placed closer to outbound lanes, while slow-movers are routed deeper into the layout to keep high-velocity paths clear.

Once outbound orders are triggered, VEENY retrieves the right pallets and delivers them to dynamic outbound lanes, sequenced by dispatch timing or customer-specific rules.

For mixed-SKU orders, operators pick cases from staging zones. BALYO’s robots then auto-collect any remaining inventory and re-store it—maintaining flow without manual forklifts.

BALYO’s Storage Optimizer continuously adjusts slotting and retrieval logic based on live inventory movement, available space, and order load. This ensures smooth traffic, reduced travel paths, and peak throughput during surge periods.

Key Operational Gains:

- Faster pallet flow from dock to high-bay and back

- Maximized cube utilization with 17m VNA stacking

- Reduced aisle traffic and faster pick paths

- Touchless restocking after partial case picking

- Consistent SLA performance across all client orders

-

Why Automation Was Critical for Their Growth

As customer volumes surged and SKU counts expanded, manual pallet handling within narrow aisle environments became a major operational bottleneck.

Traditional forklifts struggled to achieve the speed, accuracy, and space efficiency needed to meet modern 3PL service expectations.

Automation enabled faster pallet retrieval, maximized vertical storage capacity, improved selective picking efficiency, and maintained strict SLA compliance for multi-client fulfillment.

This allowed the 3PL to scale operations profitably without expanding its warehouse footprint—a critical advantage in a highly competitive logistics market.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Higher throughput, faster dispatch

- Multi-shift energy management with opportunity charging

- Achieved ROI in <18 months and saved ~$1M/year