Consult the Balyo 2024 impact report

3PL Industry Specifics

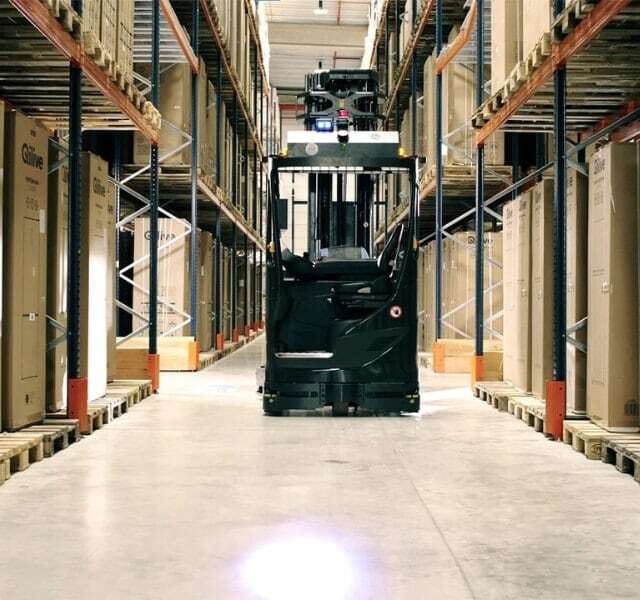

Batch picking is fast-paced, but chaotic. Manual reach trucks waste time and space—and the more they move, the more they mess up.

INDUSTRY

- Site activity : Batch order picking with automated storage & retrieval

- Quantity of shifts : 3+ shifts

- Country : USA

- Application : Inbound handling, putaway, and picking tunnel replenishment

Challenge

- Long retrieval times from high-bay racks

- Errors and congestion in tight aisles

- No scalable way to support growth

Solution

BALYO’s REACHY + LOWY combo handles it all:

- Automated full and partial pallet picking

- Delivered pallets to pickers, then returned what’s left

- Worked with all rack types—shuttle, gravity, or selective

From Manual Chaos to Scalable Automation

-

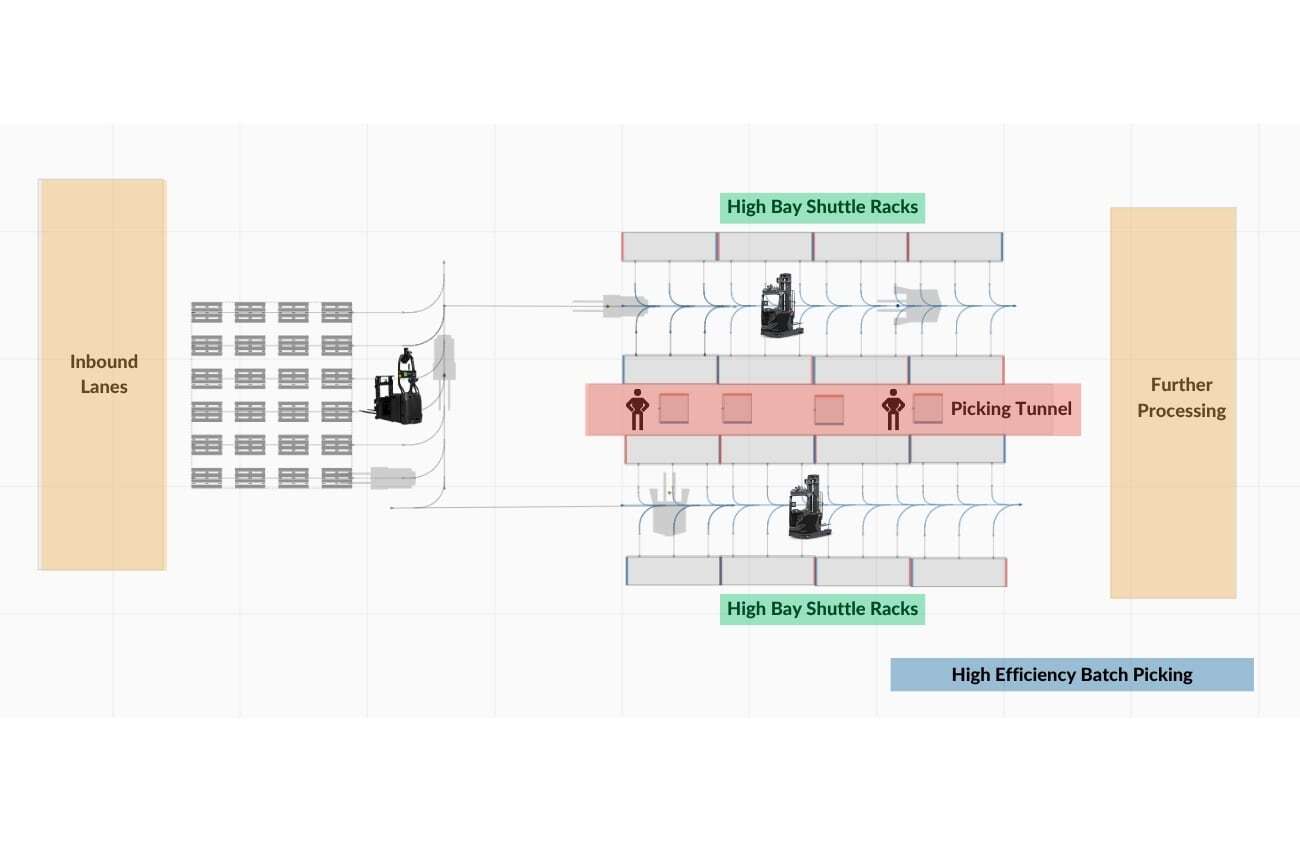

How Your Batch Picking Flow Could Transform with BALYO

Inbound pallets arriving at the receiving docks are automatically collected by BALYO’s LOWY CB stacker robots. These robots immediately sort and transfer pallets into dynamic staging lanes based on SKU type, expected outbound volume, and upcoming picking wave schedules—fully aligned with the site’s WMS.

From these lanes, BALYO’s autonomous reach trucks, REACHY, retrieve full pallets and store them in high-bay racking systems. Slotting decisions are made based on picking sequence logic, turnover velocity, and shortest path calculations to minimize robot travel.

The result? Batch picking cycles that are faster, safer, and 100% traceable—without overwhelming your pickers.

When a picking mission is triggered, REACHY robots fetch the necessary pallets and deliver them to high-access, ergonomic picking stations.

Operators then manually pick individual cases or quantities, consolidating them into outbound pallets based on shipping rules and customer-specific requirements.

Every item is tracked via barcode scanning, with real-time inventory updates pushed to the WMS—ensuring zero mismatch between picked orders and stock levels.

Once picking is complete, BALYO’s robots collect any remaining stock from the original pallets and return them to storage. The WMS dynamically assigns optimized storage locations based on:

- Available space or preferred space based on customized logic

- SKU velocity

- Future picking demand

BALYO’s robots also handle automated replenishment: when a picker’s supply runs low, REACHY can restock the station without any manual request—keeping picking operations uninterrupted.

Outbound-ready pallets are then transferred to dynamic shipping buffers. These are organized by carrier type, dispatch time, or customer priority, ensuring seamless handoff to outbound teams.

Throughout this closed-loop process, BALYO’s WMS integration and Storage Optimizer AI orchestrate:

- Collision-free robot movements

- Congestion-free picking zones

- Efficient travel path planning for retrievals

By automating the inbound-to-pick-to-ship flow, facilities eliminate manual bottlenecks, boost picker productivity, and reduce order errors—while maximizing both capacity and throughput within existing infrastructure.

-

Why Automation Could be Game-Changer for Your Growth

Manual batch picking operations often create bottlenecks, picker idle time, and heavy labor dependence—especially as SKU counts and order volumes rise.

Congested picking aisles, slow replenishment, and missed shipping deadlines can risk SLA penalties and customer dissatisfaction.

BALYO’s automation solutions can streamline pallet retrieval, pick-face replenishment, and outbound staging, allowing you to handle higher order volumes with fewer operators, reduced errors, and significantly faster cycle times—critical for scaling in a high-volume logistics environment.

-

The Scalability Factor – Ready When You Are

Our systems are designed for effortless scaling.

Adding new robots or expanding dynamic storage areas can be done without major infrastructure changes.

The same proven robotic solutions can be duplicated easily across multiple sites, delivering a true enterprise-grade automation model.

Whether you're expanding production capacity, opening new distribution centers, or scaling internationally, BALYO’s flexible model can adapt to your growth needs—ready to deliver results whenever you are.

Results

- Continuous, efficient pallet flow

- Near-perfect accuracy = no rework

- Zero rack changes needed