Consult the Balyo 2024 impact report

Manufacturing Industry Specifics

In mining, if one part’s missing—the whole site stops. Spare parts logistics has to be instant, accurate, and bulletproof.

INDUSTRY

- Site activity : Spare parts logistics for mining equipment

- Quantity of shifts : 3+ shifts

- Country : Australia

- Application : Goods-to-person replenishment and inventory management

Challenge

- Inconsistent storage and picking of spare parts

- High cost of downtime per incident

- No centralized replenishment process

Solution

BALYO combined VEENY + LOWY + AMRs:

- Stored and retrieved pallets from 17m racks

- Delivered them directly to operators or dispatch

- WMS-managed flow across entire cycle

From Manual Chaos to Scalable Automation

-

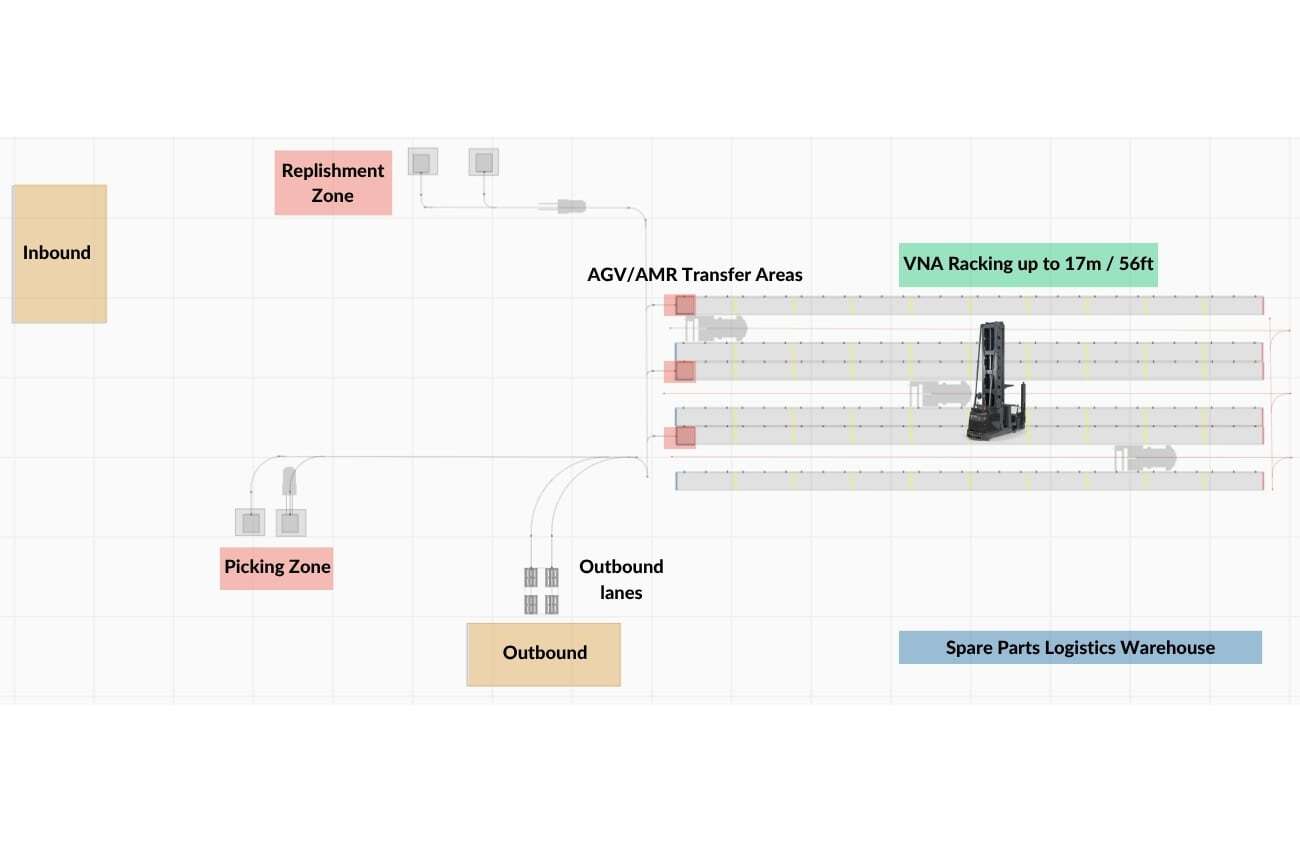

What Their Pallet Movement Looks Like Today

Spare part pallets critical for mining operations are now automatically received and staged into dynamic inbound buffer lanes by BALYO’s LOWY CB autonomous robots. These lanes are positioned near maintenance workshops and primary dispatch areas to ensure rapid availability of parts essential to ongoing operations.

Upon receipt, spare part pallets are scanned into the WMS and assigned urgency profiles based on their criticality:

- High-priority parts (vital for production line or fleet maintenance)

- Standard parts (routine maintenance)

- Long-term stock (low-movement inventory)

BALYO’s VEENY very narrow aisle (VNA) robots then transport these pallets into high-bay storage racks. VEENY systems optimize vertical storage by stacking pallets up to 17 meters high, while maintaining fast access for urgent retrievals.

When a maintenance request is triggered—either planned or emergency—the WMS sends a real-time mission to VEENY. Robots retrieve the appropriate pallet based on its urgency profile and deliver it to dynamic staging zones near workshops or directly to maintenance bays.

Dynamic cross-docking lanes support same-day high-priority movements. Urgent parts flagged during inbound scanning are automatically staged in fast-access buffer areas, bypassing deep storage and ensuring immediate deployment.

To maintain access speed, Storage Optimizer algorithms monitor stock movement and dynamically reposition pallets. This prevents slow-moving items from occupying high-priority slots and keeps high-demand parts close to dispatch points.

Outbound part orders—destined for satellite mines or third-party maintenance facilities—are also managed through the system. Once picked and staged, BALYO robots prepare pallets for dispatch with full traceability and correct load sequencing.

Throughout the entire flow, WMS and fleet managers provide real-time visibility into part locations, stock turnover, and retrieval lead times. Predictive analytics modules within the WMS help anticipate maintenance needs based on historical data, allowing critical parts to be pre-staged before formal requests are even issued.

By automating spare part logistics, the mining facility ensures maximum equipment uptime, faster repair cycles, reduced manual delays, and significantly improved operator safety across the board.

-

Why Automation Was Critical for Their Growth

In mining, every hour of unscheduled downtime can cost thousands to millions of dollars in lost production.

Manual spare parts retrieval was too slow, error-prone, and vulnerable to human availability gaps, especially during night or weekend shifts.

Automation guaranteed 24/7 immediate spare parts access, cut search and retrieval times dramatically, and eliminated the need for full-time manual warehouse staffing.

This operational resilience directly supported continuous mining operations, faster fleet maintenance, and maximum asset availability—key competitive advantages in the mining sector.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Just-in-time replenishment for critical SKUs

- Faster turnaround, higher uptime

- Fully scalable to all remote locations