Consult the Balyo 2024 impact report

Manufacturing Specifics

Flooring production lines run non-stop—and rely on fast, precise pallet and dunnage movement to stay efficient. Manual handling wastes time, causes damage, and eats up resources.

INDUSTRY

- Site activity : Tile manufacturing & material flow

- Quantity of shifts : 3+ shifts

- Country : USA

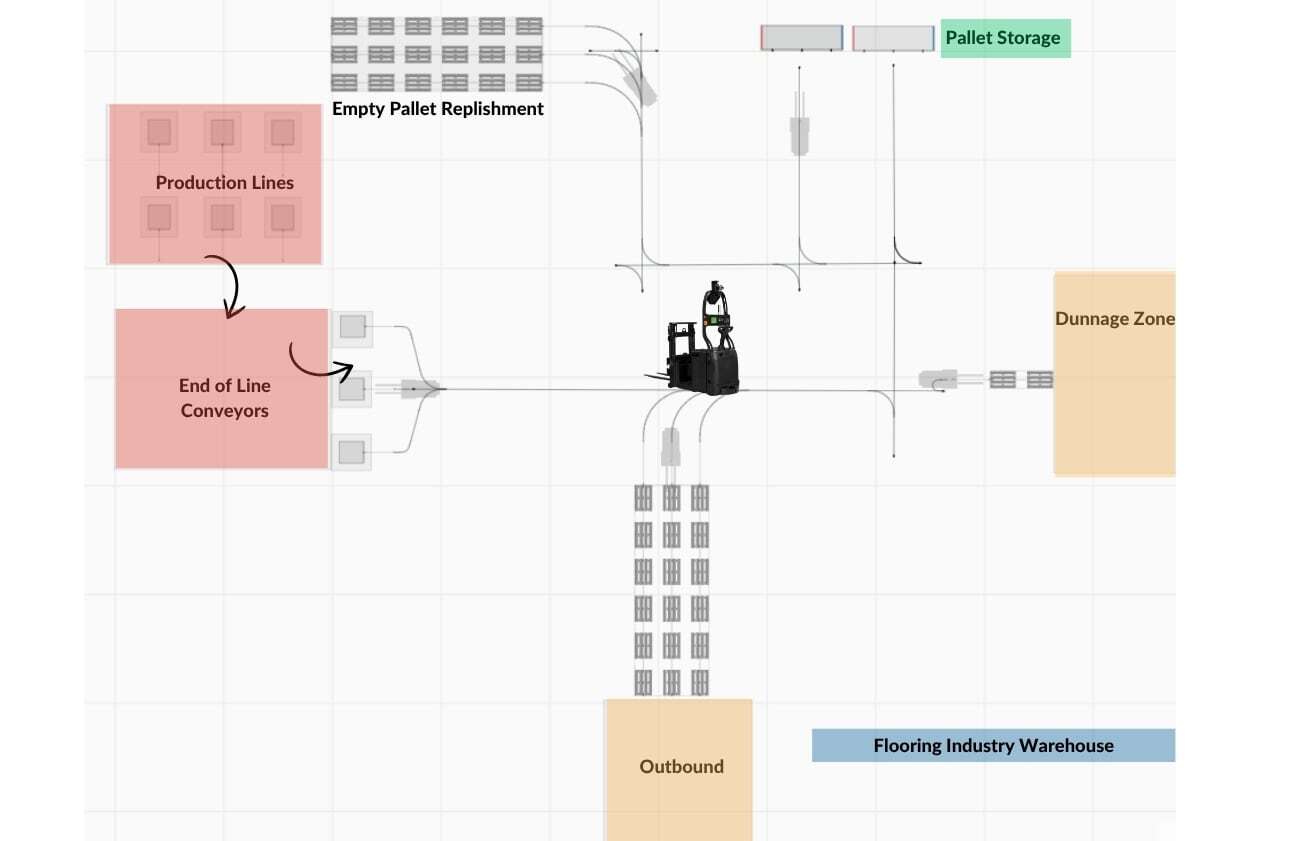

- Application : Dunnage transport and empty pallet recycling

Challenge

- Manual dunnage handling slows down production

- Empty pallet replenishment cause downtime

- Long-distance floor transport tie up labor

Solution

BALYO has deployed a fleet of driverless stackers (LOWY CB) to automate repetitive material flows:

- Efficient Dunnage Collection: Robots collect and dispose dunnage bins across zones.

- Automated Pallet Replenishment: Empty pallets delivered on-time to keep lines moving.

- Space Optimization: Pallets stacked safely in dense configurations.

From Manual Chaos to Scalable Automation

-

How Your Pallet Movement Could Transform with BALYO

In your future operations, BALYO’s LOWY CB autonomous stackers can take over the movement of empty pallets and dunnage bins across production and packaging zones. Collection points can be strategically positioned near workstations—where used dunnage accumulates and empty pallets are consumed quickly.

Robots continuously service these points, picking up full dunnage bins and delivering fresh pallets exactly where they’re needed—without human intervention or forklift interference.

This closed-loop replenishment and waste removal system operates in the background—keeping your lines flowing, your floors clear, and your teams focused.

Empty pallets are pre-staged in dynamic buffer areas. When a line’s reserve drops below threshold, your WMS automatically dispatches a replenishment mission. LOWY CB retrieves pallets from central storage or inbound docks and delivers directly to the line-side drop zone.

Everything is coordinated through BALYO’s intelligent orchestration platform:

- Real-time triggers for dunnage pickup and pallet restock

- Continuous optimization of routes and storage zones

- Full traceability and visibility of every movement

The result is a hands-free system that adapts to shifting production needs—ensuring materials are always where they need to be, when they need to be there.

With BALYO’s solution in place, your operation benefits from:

- Reduced forklift traffic and operator fatigue

- Cleaner, safer production environments

- Improved uptime and material flow

- Smarter labor use with fewer manual touchpoints

Your facility runs leaner, safer, and faster—without compromising control.

-

Why Automation is a Game-Changer for Your Growth

As production volumes grow, SKU variety expands, and workflows become more complex, manual dunnage handling can quickly create inefficiencies and safety hazards.

Forklift congestion near workstations risks delays, bottlenecks, and workplace incidents, while slow dunnage removal and pallet replenishment can threaten production continuity.

BALYO’s automation solutions can eliminate these barriers, ensuring continuous, predictable material flow without reliance on manual labor.

By automating these critical support tasks, companies can increase throughput, significantly lower incident rates, and maintain delivery reliability even during peak periods.

-

The Scalability Factor – Ready When You Are

Our systems are designed for effortless scaling.

Adding new robots or expanding dynamic storage areas can be done without major infrastructure changes.

The same proven robotic solutions can be duplicated easily across multiple sites, delivering a true enterprise-grade automation model.

Whether you're expanding production capacity, opening new distribution centers, or scaling internationally, BALYO’s flexible model can adapt to your growth needs—ready to deliver results whenever you are.

Results

- Safer, damage-free handling of fragile flooring materials

- Freed up line workers for higher-value tasks

- $750k saved annually per site with 0 stoppage for integration