Consult the Balyo 2024 impact report

Food and Beverage Industry Specifics

The food & beverage industry requires high-speed, high-volume material handling to maintain continuous production flow. Traditional material transport methods are often slow, unsafe, and time-consuming, causing inefficiencies, delays, and costly safety interventions.

INDUSTRY

- Site activity : Food manufacturing & component storage

- Quantity of shifts : 3+ shifts

- Country : USA

- Application : Automated line feeding to high-throughput manufacturing supply lines

Challenge

This high-volume food manufacturer needed an automated warehouse system to efficiently move raw materials between high-bay storage, manufacturing lines, and racking lanes. Key challenges included:

- Maximizing storage capacity without additional infrastructure.

- Reducing manual handling to minimize errors and delays.

- Ensuring seamless, high-speed operations for continuous production.

Solution

BALYO deployed a fully autonomous fleet of high-bay storage AGVs, including driverless Reach and VNA forklifts, to automate material flow without requiring any additional infrastructure.

- Digital Twin & Infrastructure-Free Setup: Simulated operations before deployment, ensuring fast setup & adaptability without stoppage.

- Versatile Line Feeding: 3D perception on the robot enables reliable handling of mixed load and pallet types.

- Storage Optimizer Solution: This proprietary technology allowed dynamic picking & dropping strategies to get maximum pallet movement efficiency and a true WMS system.

From Manual Chaos to Scalable Automation

-

What Their Pallet Movement Looks Like Today ?

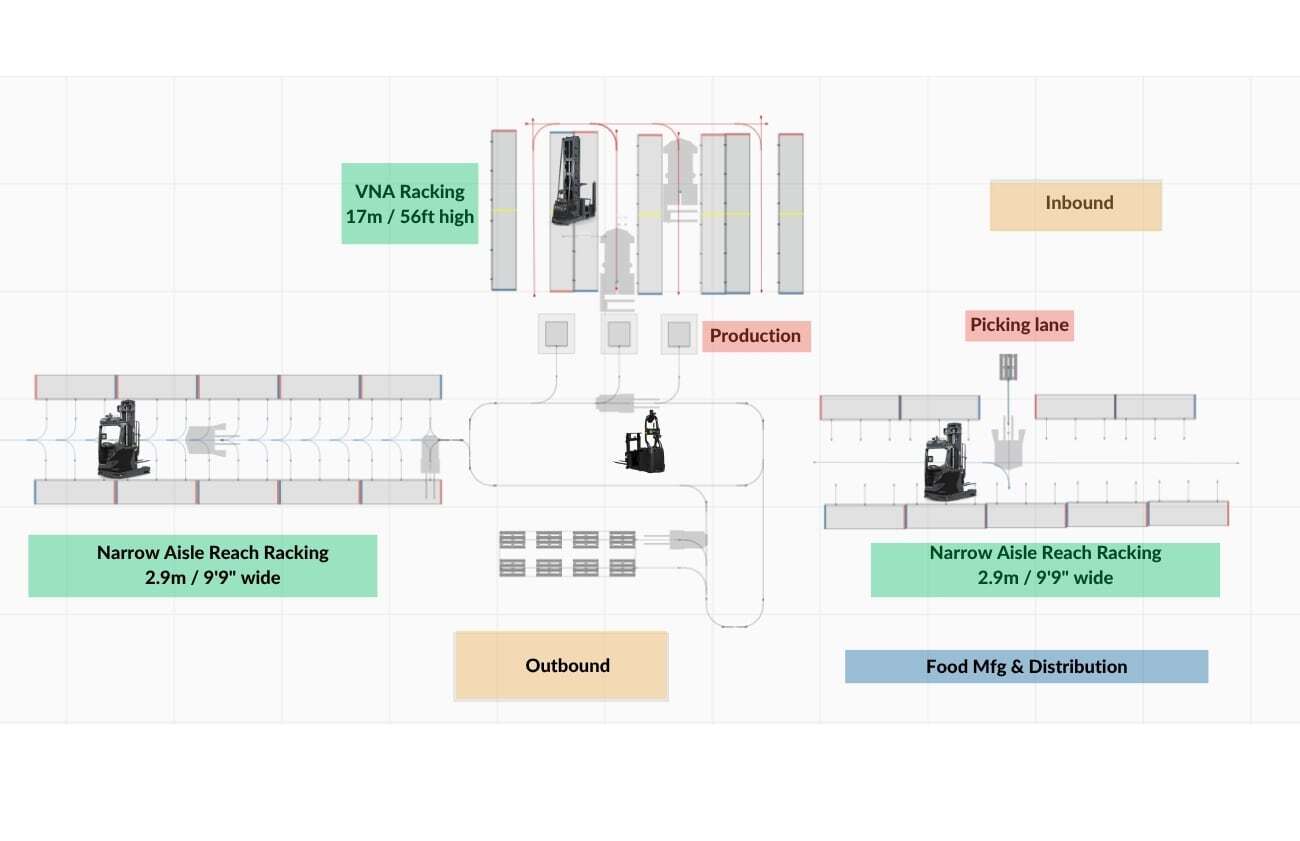

Inbound raw materials arriving at the facility are scanned and immediately directed into dynamic storage and buffer lanes. These zones are positioned between receiving and production, allowing for agile adaptation to changing demands and ensuring rapid access to materials.

These buffer lanes are managed by BALYO’s autonomous forklift fleet:

- REACHY, the autonomous reach truck

- VEENY, the very narrow aisle turret truck

They operate cohesively across both standard and very narrow aisles. Pallet movements are continuously monitored through integration with the Warehouse Management System (WMS). When a manufacturing line needs materials, the WMS automatically triggers a retrieval mission.

BALYO robots retrieve the required pallets from storage and deliver them directly to production feed zones—without human intervention.

“From receiving to production feed, pallet movement is now seamless, autonomous, and optimized in real-time.”

This hands-free flow removes bottlenecks and manual delays, ensuring smooth operation even during peak production.

The system also supports a manual picking lane to accommodate SKU-specific production needs. Here, warehouse operators:

- Pick selected items from inbound pallets

- Consolidate them onto outbound pallets based on production orders

After picking, remaining pallets are routed back into storage—again by REACHY and VEENY—ensuring no idle inventory is overlooked. The transition between manual handling and automation is seamless, sustaining high operational velocity across all warehouse zones.

At the core of this system is BALYO’s Storage Optimizer Solution, a proprietary AI-driven software that:

- Acts as the WMS for the site

- Dynamically analyzes pallet location, SKU demand, and production forecasts

- Optimizes where and how pallets are picked and stored in real time

This enables:

- Faster replenishment cycles

- Higher storage density, especially in high-bay areas

- Full visibility and traceability of raw material flow

By integrating dynamic storage, autonomous retrieval, and manual flexibility, the facility achieves a scalable and efficient material flow that supports high-volume production without disruption.

-

Why Automation Was Critical for Their Growth ?

Facing rising demand and increasing product complexity, the warehouse recognized that manual processes could no longer scale efficiently.

Relying on human labor alone risked production bottlenecks, missed customer shipments, and escalating operational costs.

Labor shortages, regulatory pressures, and unpredictable supply chain fluctuations (including tariffs and global recessions) further heightened vulnerability.

Automation guaranteed a scalable, resilient material flow while enabling faster order fulfillment.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Over $1.5M in savings generated a year in a single site

- Seamless supply chain integration, reducing manual interventions.

- Improved throughput, supporting 24/7 operations.