Consult the Balyo 2024 impact report

Paper Industry Specifics

Paper rolls are bulky and delicate. And when warehouse height is limited, you need to go dense—not up. But manual stacking eats time, space, and labor.

INDUSTRY

- Site activity : Paper production with heavy-duty warehousing

- Quantity of shifts : 3+ shifts

- Country : Japan

- Application : Conveyor-fed pallet interface and dense block stacking

Challenge

- End-of-line pallet flow was manual and error-prone

- Low ceilings limited traditional racking options

- Labor costs rising, accuracy falling

Solution

BALYO’s LOWY CB robotic stackers handled the whole cycle:

- Moved fully wrapped pallets to block storage

- Used 3D vision to stack deep, dense, and safe

- Enabled outbound retrievals aligned with WMS and existing automation like conveyors

From Manual Chaos to Scalable Automation

-

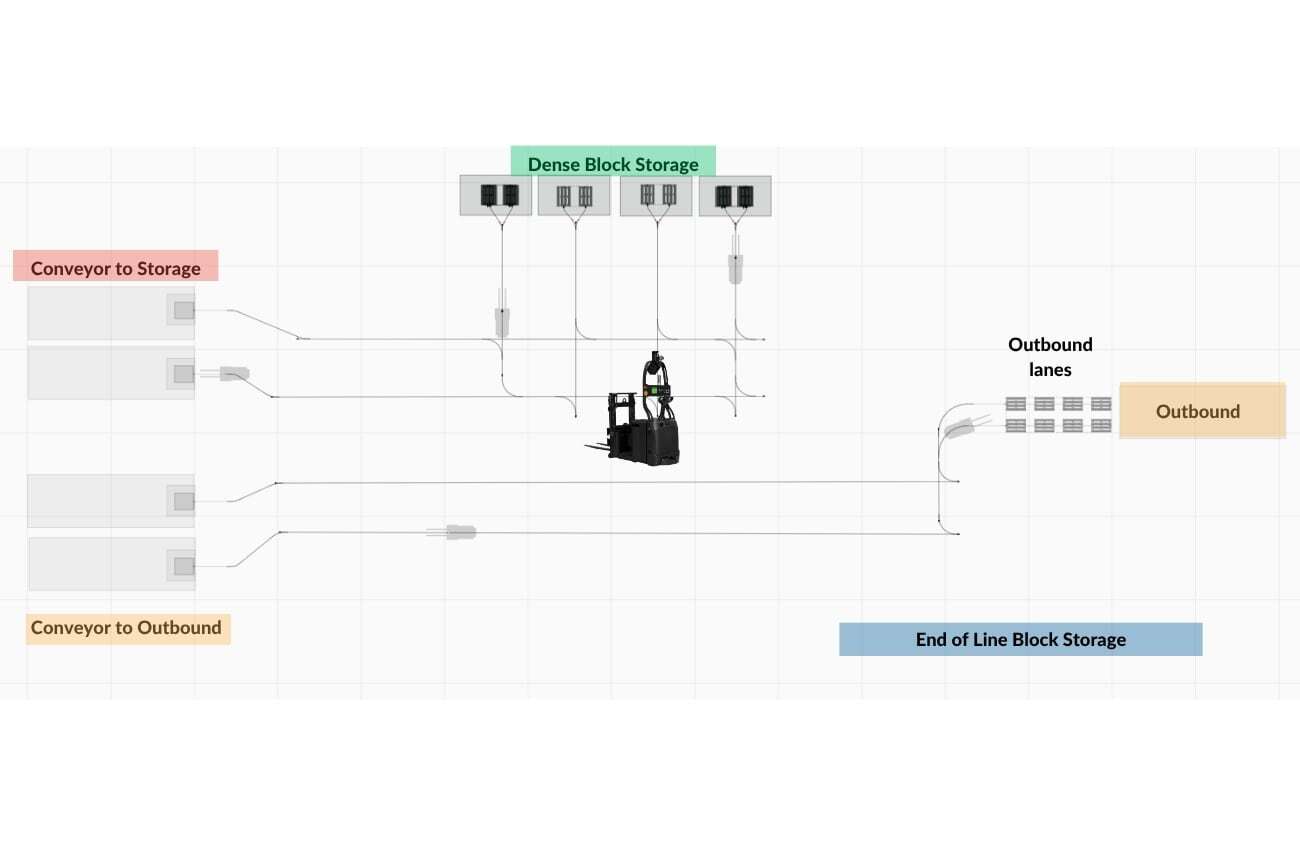

What Their Pallet Movement Looks Like Today

Finished pallets exiting the production and palletizing areas are now automatically picked up by BALYO’s LOWY CB autonomous stackers. These robots efficiently transfer pallets into dynamic block stacking zones, carefully orchestrated to maximize the facility’s available floor space.

In these zones, pallets are stacked multiple units deep and several layers high without the use of racking structures—optimizing both vertical and horizontal warehouse utilization.

Real-time SKU data, pallet dimensions, and outbound priority rules, all managed through the facility’s WMS integration, dictate the stacking order and positioning.

The result? 30% more storage capacity—without racks or new infrastructure.

Pallets designated for near-term shipping are placed in more accessible positions, while slower-moving inventory is pushed deeper into the block formation.

BALYO’s robots autonomously organize and reposition pallets as needed, dynamically adapting to daily shifts in order volume, SKU movement, and dispatch timing.

When a shipping order is triggered, BALYO’s robots navigate dense stacking formations using advanced 3D perception systems to extract the right pallet—without disturbing others or risking product damage.

This level of precision is nearly impossible to replicate with manual forklift operations.

For high-priority loads, adjacent dynamic buffer lanes are used to temporarily stage pallets before dispatch. This enables:

- Fast throughput for urgent orders

- Seamless flow for cross-dock operations

- Reduced congestion in the main storage area

Behind the scenes, BALYO’s Storage Optimizer software constantly recalibrates stacking logic based on:

- Live inventory data and turnover rates

- Weight limits and space constraints

- Predicted retrieval frequencies

If bottlenecks are detected, the system triggers autonomous reshuffling missions to preserve fast access—without operator input.

By automating dense block stacking, the facility eliminates safety risks like pallet tipping, stacking errors, or forklift traffic jams. The robots’ accuracy allows safe vertical stacking to max allowable height, achieving higher throughput and visibility—without expanding the warehouse footprint.

-

Why Automation Was Critical for Their Growth

Faced with rapid production increases and limited physical warehouse space, manual stacking methods were no longer sustainable.

Human-driven stacking introduced frequent errors, inconsistent stack heights, damaged pallets, and operational bottlenecks—especially during peak fulfillment periods.

Automation using autonomous block stacking robots maximized storage density, reduced dependency on skilled forklift operators, improved safety by eliminating tipping risks, and eliminated delays from inefficient manual retrievals.

This transition allowed the facility to scale operations efficiently without the need for costly building expansions or disruptive reconfiguration of storage layouts.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- More inventory stored in the same footprint

- Less labor, less error, more throughput

- Fully automated from production to dispatch