Consult the Balyo 2024 impact report

Manufacturing Industry Specifics

Packaging is high churn, low margin. Any delay between production and storage can throw off your entire day’s operations

INDUSTRY

- Site activity : Consumer goods packaging

- Quantity of shifts : 3+ shifts

- Country : USA

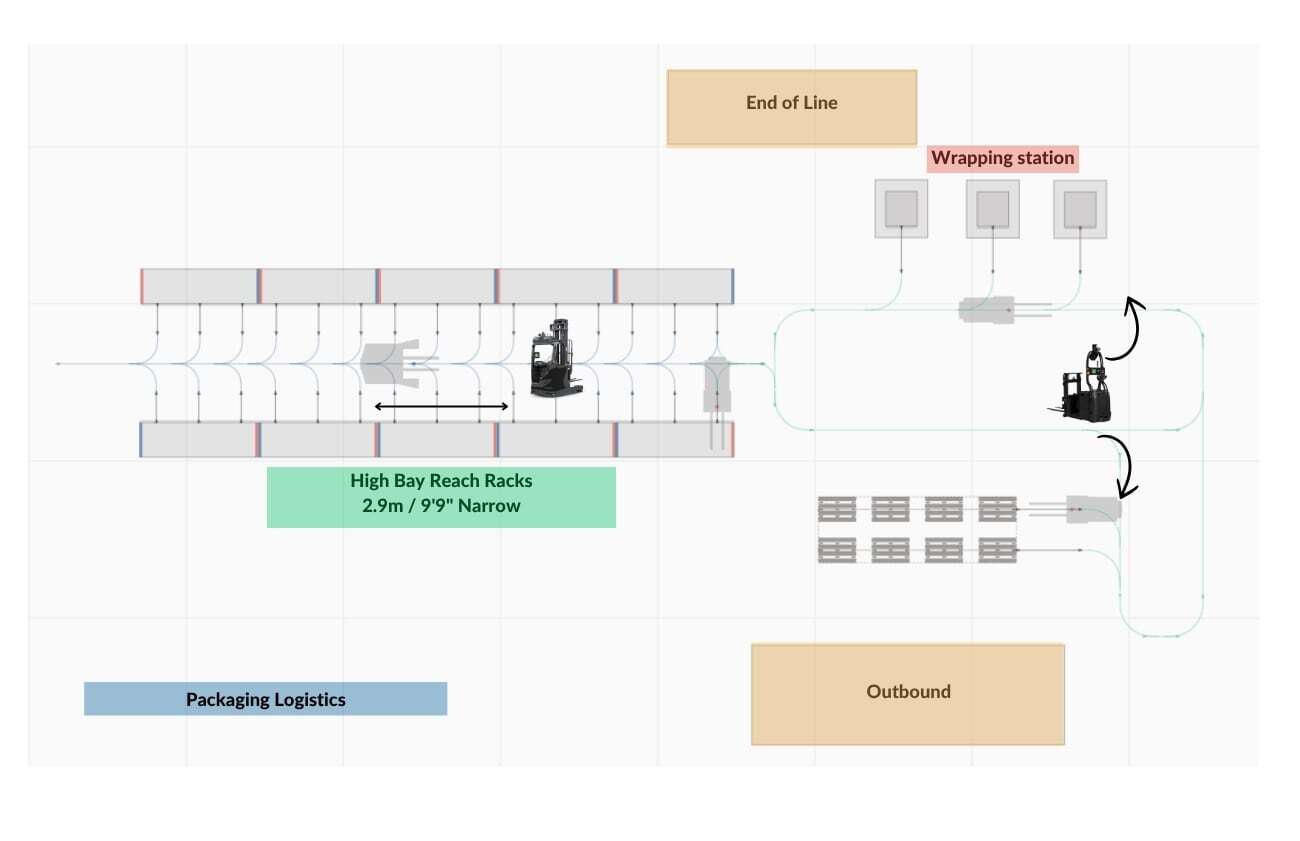

- Application : End-of-line pallet transport to high-bay storage up to 36ft

Challenge

- Manual transport is often time-consuming and risky

- No space to widen aisles or change racking

- Needs consistent, scalable throughput

Solution

BALYO has deployed a fleet of infrastructure-free counterbalanced & Reach AGVs to automate the entire post-production flow:

- LOWY CB for pickup from wrapping lines

- REACHY for high-bay rack placement

- WMS integration dispatch logic for fast outbound

From Manual Chaos to Scalable Automation

-

How Your Pallet Movement Could Transform with BALYO

In your future operations, pallets exiting the wrapping station or stretch wrapper can be automatically picked up by BALYO’s LOWY CB robots, positioned strategically at the end-of-line conveyors. These robots collect wrapped pallets immediately upon release, minimizing floor buildup and reducing forklift congestion in critical production zones.

From there, the robots transport pallets to dynamic buffer lanes—temporary holding areas that are continuously adjusted in real time via WMS integration. These lanes help align inventory with outbound shipping schedules, SKU velocity, and available storage capacity.

Once staged, REACHY, BALYO’s autonomous reach truck, seamlessly takes over. Capable of lifting up to 11 meters high, REACHY places pallets into narrow aisle, high-bay racks—efficiently and safely, even with delicate or irregular loads.

This smooth, autonomous handoff from wrapping to buffer staging to storage eliminates the need for manual forklifts and ensures continuous pallet flow across the warehouse.

For pallets that require immediate shipping—such as same-day orders or high-priority SKUs—LOWY CB can bypass high-bay storage altogether, delivering directly from the wrapping zone to dispatch staging lanes. This speeds up truck loading, reduces dwell time, and streamlines dock-side operations.

For flexible order fulfillment, designated picking zones allow operators to manually retrieve partial pallet quantities. After picking, BALYO’s robots collect the remaining pallets and return them to high-bay storage—automatically reassigned based on real-time warehouse conditions.

The entire system is orchestrated by BALYO’s Storage Optimizer Solution:

- Evaluates pallet attributes, SKU turnover rates, aisle traffic, and outbound priorities

- Continuously reallocates storage and retrieval locations to maximize flow

- Prioritizes fast-moving goods near staging areas and slower movers deeper in the racks

Throughout the operation, managers maintain real-time visibility over each pallet—from wrapping to storage to truck loading. This enables instant reactions to last-minute order changes, urgent deliveries, or production delays.

By combining automated conveyor handoffs, dynamic buffering, autonomous high-bay storage, and manual picking flexibility, this solution provides a unified, intelligent flow from production to outbound.

The result?

- Faster warehouse throughput

- Fewer material handling errors

- Synchronized operations from end-of-line to dock doors

Whether you're scaling for holiday demand or seeking day-to-day resilience, BALYO’s automated flow is built for efficiency, precision, and adaptability.

-

Why Automation is Game-Changer for Your Growth

Facing rising SKU variety, tighter shipping cut-offs, and urgent customer delivery windows, manual pallet handling can quickly become a bottleneck.

Forklift congestion near wrapping stations risks delayed loading, shipment errors, and operational slowdowns—especially during peak periods.

Automation can enable seamless transitions from wrapping to high-bay storage to dispatch staging, eliminating floor congestion, cutting transfer times, and ensuring that even last-minute orders move smoothly through your warehouse—without delays.

-

The Scalability Factor – Ready When You Are

Our systems are designed for effortless scaling.

Adding new robots or expanding dynamic storage areas can be done without major infrastructure changes.

The same proven robotic solutions can be duplicated easily across multiple sites, delivering a true enterprise-grade automation model.

Whether you're expanding production capacity, opening new distribution centers, or scaling internationally, BALYO’s flexible model can adapt to your growth needs—ready to deliver results whenever you are.

Results

- Faster truck loading & pre-staging with same resources

- Scalable deployment across facilities with 100+ robots at once

- Over $1.3M in savingsto be generated in a year in a single site.