Thanksgiving is a time for reflection, gratitude, and sharing in the fruits of our labor. The principles that make Thanksgiving a success—planning, adaptability, collaboration, and appreciation—are also fundamental when deploying Automated (or Autonomous) Guided Vehicles (AGVs) in warehouses and manufacturing facilities. As we dive into this season of gratitude, let’s explore how the lessons of Thanksgiving can inform successful AGV deployments.

How the principles that make Thanksgiving special are the same ones that drive successful automation initiatives.

The Power of Preparation

A successful Thanksgiving feast could fill up a Gantt chart of activities with the meticulous planning required to pull off a successful event. From selecting recipes to grocery shopping and setting the table, every detail matters. Similarly, deploying AGVs begins with thorough preparation.

Key Steps in AGV Deployment Preparation:

- Assessing Needs: Just as you decide what dishes suit your guests' preferences, businesses must evaluate the specific needs of their facility. Consider factors like workflow bottlenecks, peak periods, and the types of materials to be moved. Unlike Thanksgiving, you don’t have to take this burden on alone. The right AGV provider can walk you through

- Mapping the Environment: Like knowing the layout of your kitchen, mapping the facility's floor plan and identifying potential obstacles ensures AGVs can navigate efficiently. This mapping is also beneficial to start planning circuits and missions. Just like you want to take the bird straight to the table without a trip around the entire house, you want every pallet in your warehouse to go from point A to B in the straightest path possible. With the right AGV vendor, you don’t have to wait for the AGVs to be on-site to have this critical information at your fingertips.

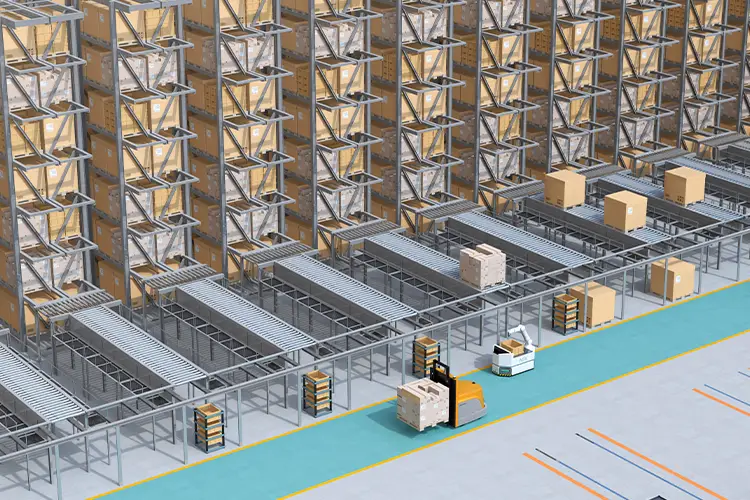

- Selecting the Right Solution: A turkey dinner isn’t for everyone; sometimes, ham or vegetarian options are better. AGVs come in an equally dizzying array of varieties and options that must be catered to the “tastes” or applications in your warehouse and manufacturing environment. From autonomous tuggers that can instantly transport heavy loads across vast distances to robotic Very Narrow Aisle turret trucks that maximize your storage density as they swiftly traverse aisles while raising pallets to a staggering 56 feet in the air. AGVs also offer a veritable cornucopia of options (or sides), from basic battery options to the more complex questions on how to handle navigation and localization. With navigation alone, you can select the more archaic wire-guided systems bored into your warehouse floor to the more elegant and modern approach of using LiDAR to navigate the warehouse and find pick and drop points.

Investing time in the planning phase prevents disruptions later, ensuring a smoother transition to automation.

Adaptability: Handling Last-Minute Changes

Even with the best-laid plans, Thanksgiving surprises are inevitable—burnt dishes, unexpected guests, or the dog running away with half of the bird. Success depends on your ability to adapt.

Similarly, AGV deployments often face unforeseen challenges. Changes in production schedules, facility layouts, or IT infrastructure can impact implementation timelines. Flexibility is crucial.

Lessons in Adaptability for AGVs:

- Invite the Right People to the Big Table: The best way to avoid Turkey Day drama is to know who is coming and how many tables to set up. The same can be said for AGV deployments. Most people assume that your logistics and supply chain positions need to be at the big table, but don’t assume that your family members in IT and finance shouldn’t automatically be relegated to the kid’s table. The truth is that you all need to be involved in the same conversation for a harmonious rollout. Speaking of rollouts…

- Don’t Do it All at Once: Just as you wouldn’t bring out the pumpkin pie with turkey, you won’t turn on every AGV at once. Conduct phased rollouts to test and refine AGV performance in real-world conditions.

- Mapping that is Always Adapting: Every Thanksgiving brings a few surprise guests. You might have to change your seating chart on the fly so your Cowboys-loving cousin isn’t sitting next to your Eagles-fan neighbor. Your warehouse brings an equal amount of surprises and you need to consider AGV’s that can call quick audibles to keep production flowing. AGVs that use LiDAR can adjust to layout changes on the fly. Many fixed infrastructure options will leave you stuck for years to come and won’t scale as your business grows.

By embracing adaptability, you’ll ensure your AGVs are equipped to handle the complexities of your operations today and tomorrow.

Appreciation: Recognizing People and Technology

Thanksgiving is a time to express gratitude for the people and blessings in our lives. When deploying AGVs, it’s important to recognize the contributions of both your workforce and the technology itself.

Expressing Gratitude in AGV Deployments:

- Celebrate Milestones: Just as you wouldn’t forget to kiss the cook or profusely thank your hosts for a joyous dinner, make sure to acknowledge key achievements during the AGV deployment process, from successful tests to full-scale operations.

- Empower Employees: Automation isn’t about replacing workers—it’s about enhancing their capabilities. Celebrate how AGVs alleviate repetitive tasks, allowing employees to focus on higher-value work.

- Value the Technology: Recognize the sophistication and reliability of AGVs. Their ability to work tirelessly, reduce errors, and optimize workflows is something to be thankful for.

Gratitude fosters a positive environment, ensuring everyone involved feels valued and motivated to succeed.

Efficiency Without Sacrificing Quality

A Thanksgiving meal is often a race against time, but rushing can lead to mistakes. Similarly, deploying AGVs should balance efficiency with quality. Cutting corners during deployment can compromise the system’s long-term effectiveness.

Keys to Balancing Speed and Quality:

- Set Realistic Timelines: Avoid unrealistic deadlines by aligning expectations with your AGV provider.

- Prioritize Integration: Ensure AGVs integrate seamlessly with existing systems like Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES).

- Monitor Performance: Regularly review key performance indicators (KPIs) to confirm the deployment is meeting objectives.

A methodical approach ensures a successful deployment that delivers lasting benefits.

Sharing the Benefits: The Joy of Giving Back

Thanksgiving isn’t just about what we receive; it’s about sharing abundance with others. AGVs, when deployed effectively, allow organizations to do more with less, ultimately benefiting customers, employees, and stakeholders.

Ways AGVs Create Value:

- Improved Customer Experience: Faster order fulfillment and reduced errors enhance customer satisfaction.

- Employee Well-Being: Automating strenuous tasks reduces physical strain on workers, improving safety and morale.

- Sustainable Operations: Efficient routing and reduced energy consumption contribute to greener operations. Also, there are AGV makers looking upstream in their supply chain and operations to deliver meaningful impact to the planet and society.

By deploying AGVs, companies create a ripple effect of benefits, driving value throughout the supply chain.

Looking to the Future

Thanksgiving reminds us to cherish traditions while embracing new possibilities. Similarly, deploying AGVs is an investment in the future, paving the way for innovation and growth.

Future-Proofing with AGVs:

- Scalability: We mentioned this earlier, but it’s worth repeating. Choose systems that can grow with your business, adding capacity as needed. AGVs represent the ultimate in flexibility versus fixed automation systems that will tie up capital and can leave huge swaths of valuable real estate unusable for months or years. Also, choose AGV’s that aren’t just automated, but rather fully autonomous.

- Data Insights: Leverage analytics from AGV operations to make data-driven decisions. Find an AGV provider who guarantees performance metrics from throughput to uptime during and after deployment.

- Innovation Opportunities: Use the time and resources saved by automation to explore new business opportunities.

AGVs are more than tools—they’re partners in progress, enabling businesses to adapt to an ever-changing landscape.

Conclusion: Gratitude and Growth

As you gather around the Thanksgiving table this year, take a moment to reflect on how the lessons of the holiday can inform your approach to deploying AGVs. From careful preparation and adaptability to collaboration and gratitude, the principles that make Thanksgiving special are the same ones that drive successful automation initiatives.

By approaching AGV deployment with the same spirit of teamwork and appreciation, you’ll not only optimize your operations but also create a workplace culture that thrives on innovation and inclusivity. So, here’s to a season of gratitude—and to the exciting possibilities AGVs bring to the table.

Happy Thanksgiving!