As Valentine's Day approaches, there's a non-traditional love story unfolding—one between logistics professionals and Automated Guided Vehicles (AGVs). For some, it’s a relationship from long ago that has gone stale over time due to aging equipment and archaic software to manage their fleet. For many, they have yet to swipe right on the idea of autonomy for the mundane movement of pallets in warehouse and manufacturing applications. Whether you need to reignite your passion for AGVs or you need to overcome the butterflies in your stomach in embracing robotics for applications, here are 6 reasons why you might just find yourself falling head over heels for AGVs this Valentine's Day.

1. AGVs Really Only Need Themselves

We’ve all those partners before that are too clingy. This one is for a few who have walked down the relationship road with AGVs before and have been left wanting. If you think of AGVs as “needy” or “all take and no give,” well then, you’re probably thinking of automated guided vehicles. Today’s autonomous guided vehicles are a confident partner that dutifully does their job - requiring very little of your time. Autonomous, or laser-guided vehicles, don’t come with the baggage of complex integrations that upend your operations with wires in the floor or reflectors everywhere. Using LiDAR and advanced SLAM navigation, there are no changes to your environment. You simply scan, plan, and then get to work.

2. AGVs Are a Ready Partner Day OneRelationships are always rocky at first. Learning what your partner likes and what you need in return can be a long and confusing process. What if there was a map of what you need and what your partner could deliver before you ever go on your first date? With robotic forklifts from companies like BALYO, the guesswork is completed before a robot even comes on-site. First, we map your environment with a 128-bit scan to capture every detail of your floor and racks. We then take that digital twin into our software tools to simulate all of your vehicles and missions. This “know before you go” type of due diligence accelerates deployments, cuts out the guesswork, and creates a working relationship between you and your new AGV partners from day one.

3. A Good Partner is a Safe Partner

We all love the bad boys (and girls) in our youth but eventually realize these daredevils are bad for us and ourselves. There is simply no room for this type of recklessness in your AGV partner. Safety is a top priority in any workplace, and AGVs take this responsibility seriously. Equipped with advanced sensors, cameras, and collision avoidance technology, AGVs navigate their surroundings with caution and vigilance, ensuring the well-being of both humans and equipment. By minimizing the risk of accidents and injuries, you get more work done and extend the lifetime value and running time of your purchase.

4. AGV Flexibility Doesn’t Lock You Down

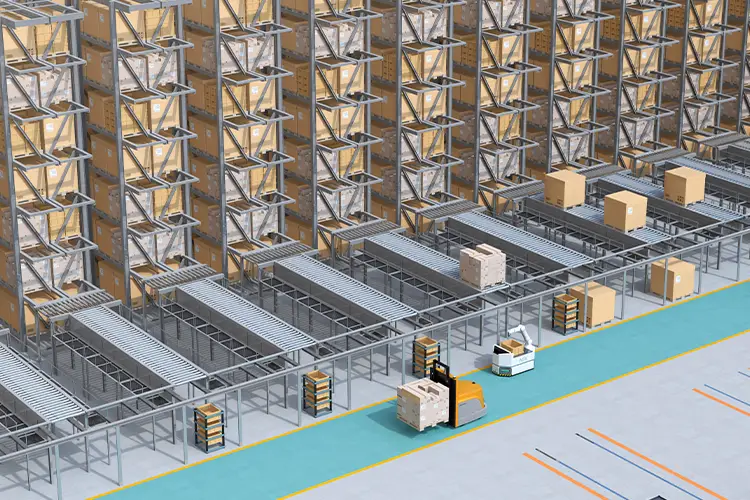

No one likes to feel trapped in a relationship. AGVs are incredibly versatile machines that can adapt to a wide range of applications and environments. Whether it's navigating through narrow aisles, reaching new heights in racking, or adjusting to changes in workflow, AGVs are up to the challenge. Their modular design and customizable features make them highly adaptable to evolving operational requirements, allowing you to tailor their capabilities to suit your specific needs. Unlike AS/RS systems or complex conveyors, AGVs grow with your business rather than leave it locked down. With AGVs by your side, you have the flexibility to tackle any new logistical challenges that come your way.

5. A Cheaper Date Over Time

While the initial investment in AGV technology may seem daunting, the long-term cost savings are undeniable. AGVs require minimal maintenance compared to traditional material handling equipment, resulting in lower repair expenses and reduced downtime. Additionally, their ability to operate continuously and efficiently helps minimize labor costs and optimize resource utilization, leading to significant savings over time. With AGVs, you can achieve operational excellence without breaking the bank.

6. AGVs Make You a More Productive Person

The best relationships are the ones that make you a better person. AGVs are productivity powerhouses that can supercharge your operations and drive business growth. By automating repetitive and labor-intensive tasks, AGVs free up valuable human resources to focus on more strategic activities. This not only increases overall productivity but also allows you to scale your operations more efficiently to meet growing demand. With AGVs as your trusted allies, you can achieve higher throughput, faster cycle times, and greater operational efficiency.

AGVs are more than just robots—they're indispensable partners that can revolutionize your operations, drive business growth, and enhance your competitive edge. This Valentine's Day, why not show some love to AGVs and appreciate the countless ways they contribute to your success? Whether it's their efficiency, reliability, safety, or versatility, there's no denying the undeniable charm and appeal of AGVs.