Consult the Balyo 2024 impact report

Food and Beverage Industry Specifics

Cold-chain logistics has no room for delays—or broken goods. Every second matters when you're handling perishable, temperature-sensitive inventory.

INDUSTRY

- Site activity : Cold chain food production & logistics

- Quantity of shifts : 3+ shifts

- Country : France

- Application : End-of-line pallet handling and refrigerated storage

Challenge

- Manual forklifts caused delays and damages

- Needed FIFO control for expiry-driven storage

- Cold environment limited human operations

Solution

BALYO deployed REACHY robots with:

- Expiry-based pallet placement using WMS data

- Safe navigation in cold, narrow aisles

- Dense outbound staging for fast dispatch

From Manual Chaos to Scalable Automation

-

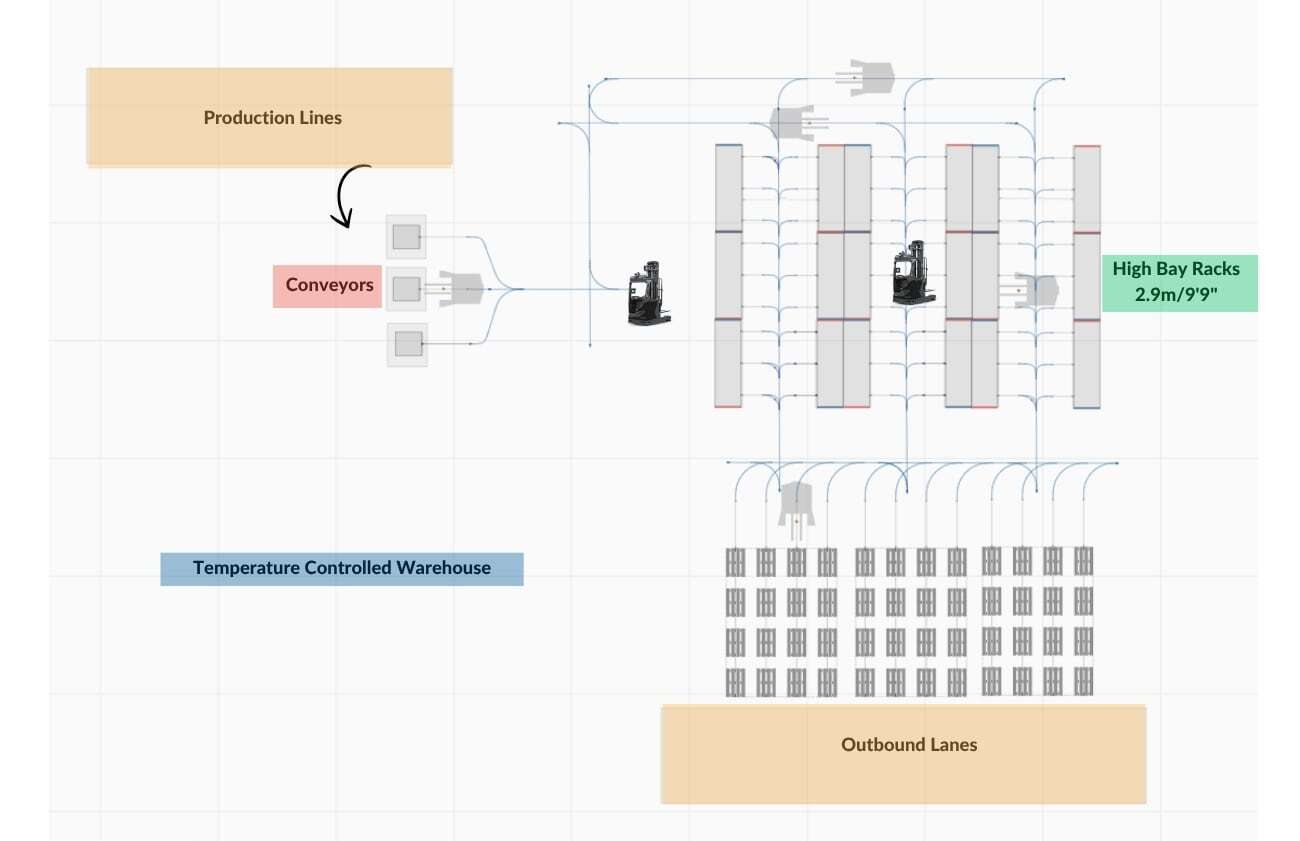

What Their Pallet Movement Looks Like Today

Upon arrival at the facility, raw material pallets are automatically received by BALYO’s LOWY CB robots and staged in dynamic cold storage buffer zones. These zones are positioned near temperature-controlled production lines, allowing quick pallet access while preserving cold chain integrity.

BALYO’s REACHY autonomous reach trucks then transfer the pallets into high-bay racking within refrigerated areas. REACHY is cold-rated and designed to stack pallets up to 11 meters high—maximizing space while maintaining rapid access.

No breaks in the cold chain. No manual mistakes. No compromise on shelf life.

Every inbound pallet is tracked via WMS—timestamped and logged with SKU data. BALYO’s Storage Optimizer prioritizes where pallets are placed and how they’re retrieved, based on real-time expiration tracking and FIFO (First In, First Out) logic.

When production lines need replenishment, the WMS triggers a mission. BALYO robots retrieve the oldest qualifying pallet and deliver it directly to line-side staging zones—automatically and without delay.

Once finished goods are produced and packed, BALYO robots transfer the pallets into outbound staging lanes. These lanes are designed to:

- Minimize dwell time

- Reduce cold exposure during transitions

- Speed up trailer loading into temperature-controlled trucks

Storage Optimizer algorithms continuously monitor pallet flow, re-slotting pallets during off-peak hours based on:

- Upcoming production orders

- SKU turnover

- Predicted replenishment demand

The entire operation minimizes:

- Door open times

- Operator exposure to cold environments

- Inventory dwell in transition zones

By combining temperature-resilient robotics, automated FIFO compliance, and dynamic staging, this cold storage setup achieves high throughput without breaking the cold chain. Inventory accuracy, food safety, and production scalability are all built-in.

-

Why Automation Was Critical for Their Growth

In cold-chain food manufacturing, every minute of delay between receiving, storing, and replenishing pallets risks product degradation and costly compliance failures.

Manual pallet handling in refrigerated zones was slow, physically exhausting for workers, and prone to errors—particularly during peak production periods.

Automation not only accelerated replenishment cycles and minimized exposure of sensitive products to non-compliant temperatures but also safeguarded employees by reducing their time in harsh environments.

By automating both inbound material flow and outbound finished goods handling, the facility achieved 24/7 production continuity, perfect shelf-life management, and full cold chain traceability—essential for scaling operations while maintaining quality standards.

-

The Scalability Factor – Ready for More

The current system is designed with scalability at its core.

Adding new robots to cover additional production lines or expanding dynamic storage areas requires no major infrastructure changes.

The same robotic solution can be duplicated seamlessly across multiple facilities, creating a true enterprise-grade solution, and allowing each warehouse to know before they go.

Whether expanding production capacity, opening new distribution centers, or scaling internationally, the customer now has a proven, flexible, and easily replicable automation model ready to meet future growth demands.

Results

- Increased freshness, reduced waste

- 24/7 automated storage and retrieval

- Adapted to existing racks, no disruption