Our robotic solution can be integrated into the existing architecture using an IT interface, additional equipment or robot coded intelligence. Mission orders can be retrieved and sent to our robot fleet management system using:

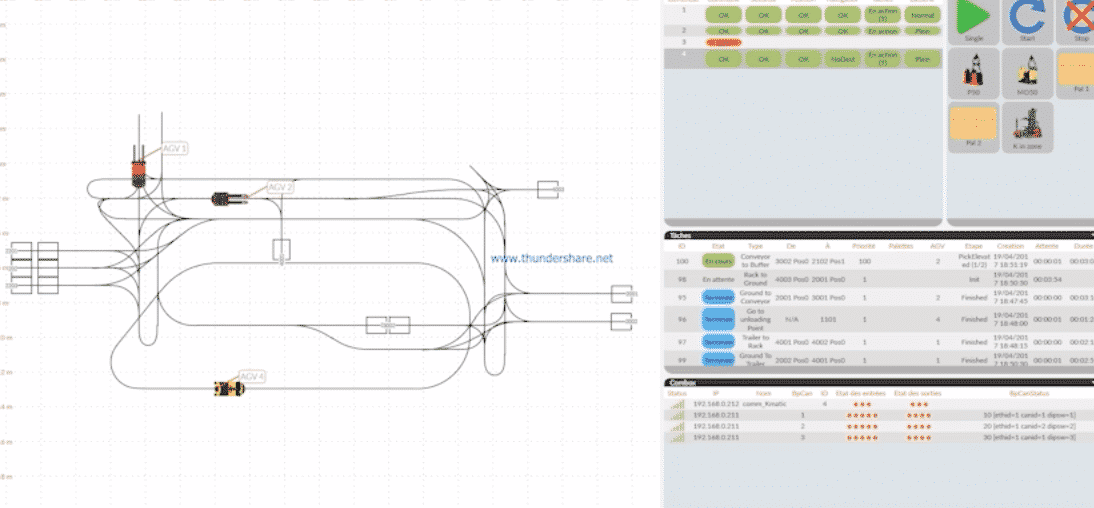

Traffic management is an essential part of our technology, increasing the overall system intelligence.

Robot Manager supervises the robot network in real time, granting access or holding back robots to avoid congestion and secure transit.

It governs movements of each autonomous vehicle on the circuit and can hold a robot in a specific area according to robot virtual size and other mobile robots’ positions. The Robot Manager, acting as a traffic controller, will allow robots to move on the circuit according to installation needs avoiding deadlock.

There is nothing better than a live trial to give you the best overview of what our robots are capable of. That is why we give you the opportunity to get a Proof of Concept in your facility

Learn more about our products and technology, sign up to our newsletter!